Bolts & Screws

TSM Technology's Premium Bolts & Screws

We specialize in high-performance bolts and screws crafted from premium titanium and nickel alloys (Monel®, Inconel®, Hastelloy®). Engineered for extreme conditions, our fasteners undergo rigorous testing to meet ASTM/ASME, EN, DIN, and JIS standards. With decades of metallurgical expertise, TSM delivers corrosion-resistant, high-strength bolting solutions trusted in aerospace, energy, and chemical processing applications. Our full-process capabilities—from alloy melting to final testing—ensure reliability where it matters most.

Product Standards and Available Materials Selection

| Material Category | Available Grades | Standards | Typical Applications |

|---|---|---|---|

| Titanium | Grade 1, 2, 3, 4, 5,7, 9, 12 |

DIN912 |

Aerospace fasteners, marine hardware, medical implants |

| Nickel Alloys |

Inconel601 |

Chemical processing, oil & gas equipment, nuclear reactors |

|

| HastelloyC22 HastellayC276 |

|||

| Aluminum | 6061-T6, 7075-T6 | Aircraft structures, lightweight industrial fasteners |

|

| Copper Alloys | C11000, C36000 | Electrical components, plumbing systems, marine hardware |

- Other standard or non-standard bolts can be customized.

Why Choose TSM?

TSM Technology delivers mission-critical bolting solutions engineered to withstand extreme conditions. Our titanium and nickel alloy fasteners are trusted where standard steel fails:

Technical Partnership

Custom-engineered solutions for your specific operational challenges

Corrosion-proof performance

Resists acids, seawater, and high-temperature oxidation

Certified Reliability

Full compliance with ASTM/ASME, EN, and DIN standards, and ISO 3506.Batch-tested bolts/screws for turbines, subsea valves, and sour gas pipelines.

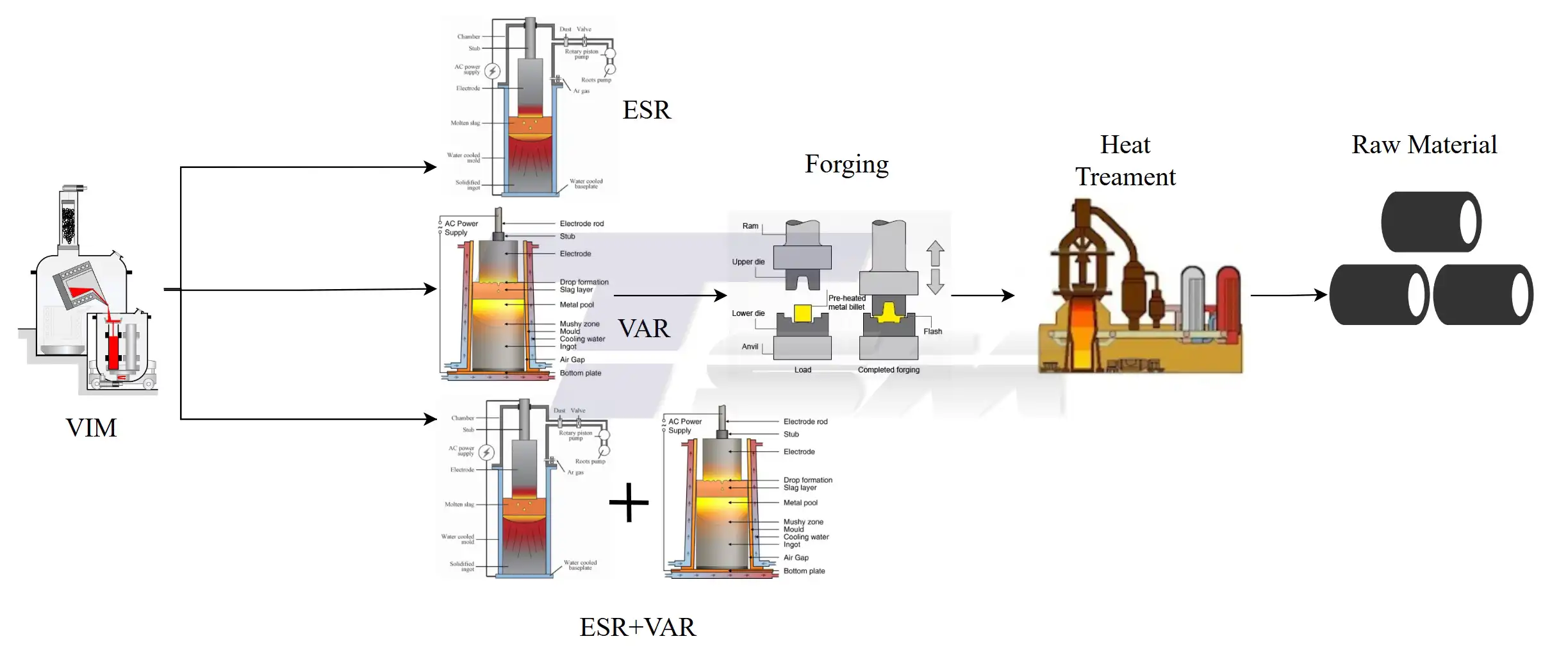

VIM/ESR Ultra-Pure Material Integrity

Vacuum Induction Melting + Electroslag Remelting ensures Ni ≥ 99.6% (ASTM B160), O₂ ≤ 80ppm, N₂ ≤ 50ppm. Eliminates inclusions for corrosion-proof performance in chemical reactors.

Trusted by Industry Leaders

TSM's high-performance bolts and screws are specified for critical applications including aerospace (engine mounts, airframe assemblies), oil & gas (subsea valves, wellhead equipment), chemical processing (heat exchangers), and power generation (turbine fastener).

Custom Large-Scale Bolt & Screw Fabrication

Manufacture bolts/screws from 20mm to 1500mm diameter (5-axis CNC) and ≤5-ton weights. Ideal for heavy machinery, marine propellers, and infrastructure projects requiring oversized fasteners.

To learn more about TSM fasteners, please visit our fasteners website.

Bolt & Screw Types

|

Type |

Hex Bolts & Screws |

Flanged / Collared Hex Bolts |

Hex Structural Bolts |

Square Head Bolts |

Round Head Bolts |

|

Countersunk Head Bolts |

Eye Bolts |

T-Head Bolts |

U-Bolts |

Hex Alobular Bolts & Screws |

|

|

12 Point Bolts |

Wheel Bolts |

Single End Bolts |

Single End Bolts |

Thread Rods |

|

|

Available Size: |

M1--M64 x L 6-300mm |

||||

Key Processes:

Cold forging for superior grain structure (up to M36 size)

Rolled threads (vs. cut) for 30% higher fatigue life

Passivation & coatings – Xylan® for friction control, Ni-PTFE for chemical resistance

Raw Material Processes

Quality Assurance

Material Certifications: Mill test reports per EN 10204 3.1

Dimensional Checks: Optical comparators for thread pitch/diameter verification

Mechanical Testing: Tensile, hardness (Rockwell C), and Charpy impact tests

NDT: Eddy current testing for surface defects

Industries We Serve

- Aerospace Bolts & Screws

TSM's titanium bolts secure jet engine components and airframe structures, withstanding 800°C+ thermal cycling. AS9100-compliant screws feature precision threads (±0.05mm) for vibration-resistant performance.

-

Oil & Gas Pipeline Bolts

Corrosion-resistant Monel® bolts maintain seal integrity in sour gas wellheads and subsea valves. Our ASTM A193 B7M screws resist H₂S/CO₂ corrosion at 10,000 PSI pressures.

-

Nuclear Power Fastening Systems

Grade B7 alloy steel bolts anchor reactor vessel flanges with full traceability per ASME III. Zirconium alloy screws minimize neutron absorption in fuel assemblies.

-

Chemical Processing Screws

Hastelloy® C276 bolts prevent acid leakage in reactors and heat exchangers. PTFE-coated screws handle chlorine/alkali exposure with ASTM F594 certification.

-

Marine & Desalination Bolts

Super duplex stainless steel screws resist saltwater pitting in ship engines and desal pumps. Anodized titanium bolts deliver 20+ year service in seawater immersion.

Production and Package

FAQ

Q: How does VIM/ESR improve bolt performance in corrosive environments?

A: Vacuum Induction Melting (VIM) + Electroslag Remelting (ESR) ensures Ni ≥ 99.6% purity (ASTM B160), O₂ ≤ 80ppm, N₂ ≤ 50ppm. Eliminates inclusions for sour gas/pipeline corrosion resistance.

Q: Can TSM produce non-standard screw geometries?

A: Yes. We prototype complex bolt/screw structures (e.g., flanged heads, asymmetric threads) in 3 weeks. 5-axis CNC enables ±0.05mm precision for R&D validation.

Q: What certifications do TSM bolts and screws meet?

A: All fasteners exceed ASTM/ASME, EN, and DIN standards with full traceability. Batch-tested for nuclear, subsea, and turbine applications.

Q: Are your titanium bolts suitable for seawater immersion?

A: Absolutely. Our Grade 5/23 titanium bolts resist galvanic corrosion in marine/desalination systems. Validated for 20+ year service life per ASTM F468.

Contact Us

Ready to enhance your projects with our superior bolts and screws? Contact our expert team today for quotes, technical support, or custom inquiries.

Email:info@tsm-technology.com

- 1