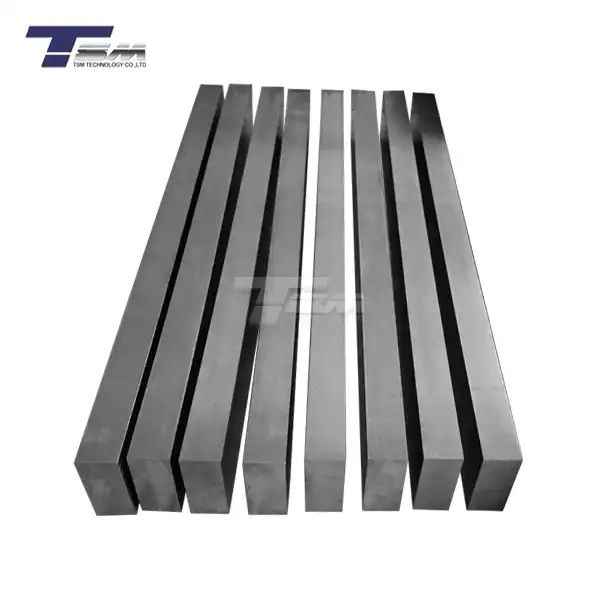

Nickel Square Bar

Supply Ability: 300 Tons/month

Grade:Nickel 201/200,Inconel 718/600/625/X-750

Standard: ASTM B164

Size: 10mm×10mm - 150mm×150mm

Tolerance: ±0.1mm (precision ground available)

Material Certification: MTC and SGS test reports available

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Square Bars Manufacturer and Supplier

At TSM Technology Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of premium Nickel Square Bars. With over 14 years of experience in the superior nickel alloy industry, we deliver top-quality products to precision engineering and machine shops worldwide. Our products are renowned for their exceptional strength, corrosion resistance, and versatility across various demanding sectors, including pharmaceutical, marine, oil and gas, and medical industries.

What are Nickel Square Bars?

The Nickel Square Bars are solid, square-shaped metal bars made primarily from nickel or nickel alloys. These high-performance materials offer excellent mechanical properties, corrosion resistance, and thermal stability, making them ideal for use in challenging environments and critical applications.

Specification

| Dimension | Range |

|---|---|

| Side Length | 6mm - 300mm |

| Length | Up to 6000mm |

| Tolerance | ±0.1mm to ±0.5mm (depending on size) |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.9 g/cm³ |

| Melting Point | 1455°C (2651°F) |

| Thermal Conductivity | 90.9 W/m·K |

| Electrical Resistivity | 6.84 x 10-8 Ω·m |

| Yield Strength | 148 MPa (minimum) |

| Tensile Strength | 462 MPa (minimum) |

Product Standards

Our products comply with international standards, including:

- ASTM B160 / B161

- AMS 5663 / 5664

- DIN 17740 / 17750

- EN 10204 3.1

Features of Nickel Square Bars

- Excellent corrosion resistance

- High strength and durability

- Superior heat resistance

- Good electrical conductivity

- Non-magnetic properties

- Exceptional machinability

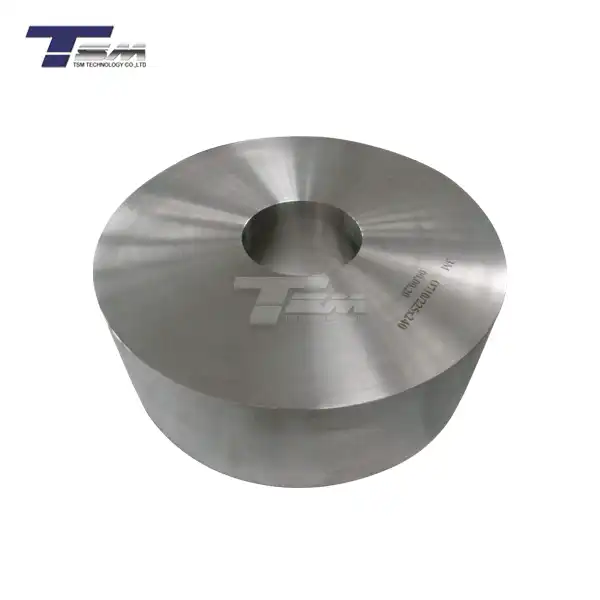

Production Process and Quality Inspection

At TSM Technology, we produce high-quality nickel square bars through an advanced, integrated manufacturing process that begins with rigorous raw material selection and testing. Our production utilizes precision melting and alloying in controlled environments, followed by multi-stage forming processes including hot extrusion, forging, and cold drawing to achieve optimal material properties. The bars then undergo precision CNC machining to meet exact dimensional tolerances, along with customized heat treatment to enhance mechanical performance, before receiving final surface finishing.

Quality is assured at every stage through comprehensive testing protocols. We conduct full chemical composition analysis, mechanical property verification, and advanced non-destructive testing to guarantee material integrity. Each bar is meticulously inspected for dimensional accuracy and surface quality, ensuring compliance with the most stringent industry standards. Our technical capabilities include specialized processes like vacuum induction melting for purity control and electroslag remelting for microstructure refinement, supported by complete traceability throughout production. This end-to-end control over both manufacturing and quality assurance enables us to deliver nickel square bars that consistently meet the demanding requirements of critical applications across industries.

Applications

Nickel Square Bars find extensive use in various industries:

- Chemical Processing: Reactors, heat exchangers, and valves

- Aerospace: Engine components and structural parts

- Marine Engineering: Propeller shafts and offshore platforms

- Electronics: Connectors and switches

- Oil & Gas: Downhole tools and wellhead components

Factory

Why Choose TSM Technology?

TSM Technology stands out as your preferred supplier of products due to our cutting-edge material technology and purity control, ensuring high-grade products. Our precision manufacturing and process advantages deliver ultra-tight tolerances and customized surface treatments like sandblasting, pickling, and polishing. We maintain a comprehensive quality assurance system with certifications including ISO 9001/13485, AS9100D, and NADCAP. Our commitment to traceability, sustainable production, and industry-specific solutions sets us apart. We offer rapid response to special requirements, global supply chain assurance, and strategic raw material reserves, making us your ideal partner for all nickel alloy needs.

Package and Shipment

FAQ

- Q: What is the minimum order quantity for products?

A: Our minimum order quantity is 100 kg, but we can accommodate smaller orders for special requirements. - Q: Can you provide custom sizes for products?

A: Yes, we offer custom sizing to meet your specific needs. Contact our sales team for details. - Q: What is the lead time for product orders?

A: Typical lead times range from 2-4 weeks, depending on quantity and specifications. - Q: Do you offer material certificates with your products?

A: Yes, we provide full material traceability and test certificates with every order. - Q: Are your products suitable for use in marine environments?

A: Absolutely. Our nickel alloys offer excellent corrosion resistance in marine applications.

Contact Us

Ready to elevate your projects with our premium Nickel Square Bars? Contact TSM Technology today for expert advice, custom solutions, and competitive pricing.

Email: info@tsm-technology.com