Nuts

Nuts Supplier | TSM Technology – High-Performance Industrial Nuts

TSM Technology provides precision-engineered Nuts crafted from high-performance titanium and nickel alloys. Since 2011, we've supported global aerospace, energy, chemical, and industrial sectors with corrosion-resistant, high-strength fastening solutions. Backed by ISO-certified production, advanced processing, and strict quality control, our fasteners deliver reliability in the most demanding environments. Explore standard and custom nut configurations designed for critical applications.

Nuts Standards and Available Materials Selection

| Material Category | Available Grades | Standards | Typical Applications |

|---|---|---|---|

| Titanium | Grade 1, 2, 3, 4, 5,7, 9, 12 |

DIN912 |

Aerospace fasteners, marine hardware, medical implants |

| Nickel Alloys |

Inconel601 |

Chemical processing, oil & gas equipment, nuclear reactors |

|

| HastelloyC22 HastellayC276 |

|||

| Aluminum | 6061-T6, 7075-T6 | Aircraft structures, lightweight industrial fasteners |

|

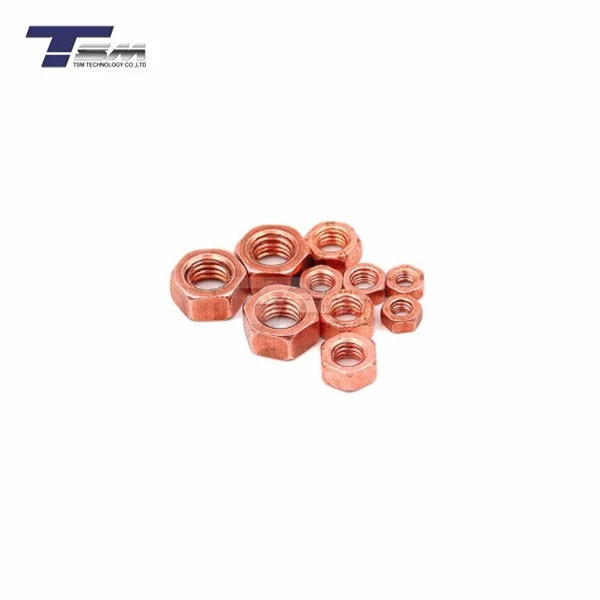

| Copper Alloys | C11000, C36000 | Electrical components, plumbing systems, marine hardware |

Why Choose TSM's Nuts?

TSM Technology manufactures precision nuts engineered to match our premium bolts and screws, ensuring complete fastening system integrity.

Flexible Manufacturing for All Needs

TSM offers precision forging solutions compliant with ISO 2768 standards: Free forging (±1.5mm, m-class) for custom/large fasteners, die forging (±0.8mm, m-f-class) for high-volume production, and ring rolling (±0.5mm, f-class) for critical pressure vessel components. Our flexible processes ensure optimal tolerance control from standard to precision applications.

Engineered for Perfect Fastener Compatibility

Engineered for perfect fastener compatibility, our products are CNC-machined to Class 6H/7H thread tolerance (ISO 965). This precision ensures they are perfectly matched with TSM's premium bolts and screws, guaranteeing complete system integrity.

Advanced Material Expertise

Leveraging advanced material expertise, we specialize in Titanium (Gr.1-Gr.5), nickel alloys (Inconel®/Monel®), and specialty steels. These materials are engineered to be corrosion-resistant for seawater/chemical exposure and heat-resistant up to 1300°C.

Uncompromising Quality Assurance

We uphold uncompromising quality assurance throughout our manufacturing process, ensuring the reliability and integrity of every product. We are compliant with ASTM E1742 and Penetrant Testing (PT), adhering to ASME Section VIII. Furthermore, we provide complete material traceability verified by EN 10204 3.1/3.2 certification.

Scalable Production Capabilities

With a focus on supporting the entire product lifecycle, we offer scalable production capabilities, seamlessly transitioning your projects from prototype to mass production. Our extensive capacity handles oversized nuts up to 36 inches in diameter, ensuring we meet your most demanding manufacturing needs efficiently and reliably.

Technical Partnership Approach

At TSM Technology, we partner with clients to develop custom fastener solutions, offering specialized thread profiles, anti-galling PTFE/Xylan® coatings, and engineering support including CAD design and FEA analysis for mission-critical applications

Nut Types & Standards

|

Type |

Hex Nuts |

Flanged / Collared Hex Nuts |

Corn Nuts |

Locking Nuts |

Slotted Nuts |

|

Round Nuts |

T-Nuts |

Tinnerman-Style Nuts |

Snap-In Nuts |

Wheel Nuts |

|

|

Available Size: |

M1-M64 |

||||

Manufacturing Process

- Material Forging - Hot/cold forming for grain structure optimization

- Thread Cutting - Precision CNC thread milling (vs. tapping)

- Heat Treatment - Solution annealing/aging for nickel alloys

- Surface Finishing - Passivation, electropolishing, or Xylan® coating

Quality Assurance

- Dimensional Checks - Optical comparators for thread pitch/diameter

- Mechanical Testing - Proof load testing per ISO 898-2

- NDT - Liquid penetrant inspection for surface defects

Custom Solutions(Engineering Support)

- Special Threads - UNJ, MJ, or custom profiles

- Unique Coatings - PTFE-impregnated for galling prevention

- Prototyping - Rapid sampling in 15 working days

Industries We Serve

- Oil & Gas Exploration

We manufacture pressure vessel fastener nuts via precision ring rolling (±0.5mm), engineered to withstand pressures exceeding 15,000 PSI. Our rigorous PT/RT testing, conducted per ASME standards, prevents leaks in critical drilling rigs and pipeline infrastructure.

- Power Generation

For nuclear and thermal power plants, we utilize high-volume die forging to produce turbine fastener nuts with an exacting ±0.8mm tolerance. Comprehensive ultrasonic testing (detecting flaws ≥0.8mm) guarantees their reliability in high-vibration environments.

- Marine & Shipbuilding

Our free-forged fastener nuts (±1.5mm) are designed to withstand severe saltwater corrosion in ship engines and offshore platforms. We perform PT testing compliant with ASME Section VIII to ensure the integrity of subsea valve assemblies.

- Heavy Machinery & Construction

We provide oversized fastener nuts, produced through free forging (±1.5mm), for anchoring heavy mining equipment and large cranes. UT/RT testing ensures these critical components are defect-free for secure, load-bearing, and seismic structures.

Package

FAQ

Q: What tolerance can be achieved for large Nut using free forging?

A: Free forging produces oversized it within ±1.5mm tolerance, ideal for heavy machinery and custom shapes.

Q: How precise are batch-produced Nuts via die forging?

A: Die forging ensures ±0.8mm dimensional tolerance for high-volume products, guaranteeing consistency in mass production.

Q: Which process delivers ±0.5mm precision for the pressure vessel Nut?

A: Ring rolling technology achieves ±0.5mm tolerance for seamless pressure vessels this product, meeting aerospace/energy demands.

Q: How are internal defects detected in high-strength it?

A: Ultrasonic testing (UT) identifies flaws ≥0.8mm; RT complies with ASTM E1742, and PT meets ASME Section VIII standards.

Q: Can you manufacture ASME-compliant pressure vessel Nuts?

A: Yes. Ring-rolled products undergo RT/PT per ASME Section VIII with ±0.5mm tolerance for critical applications.

Contact Us

Ready to enhance your projects with our superior Nuts? Contact our expert team today for quotes, technical support, or custom inquiries.

Email:info@tsm-technology.com

- 1