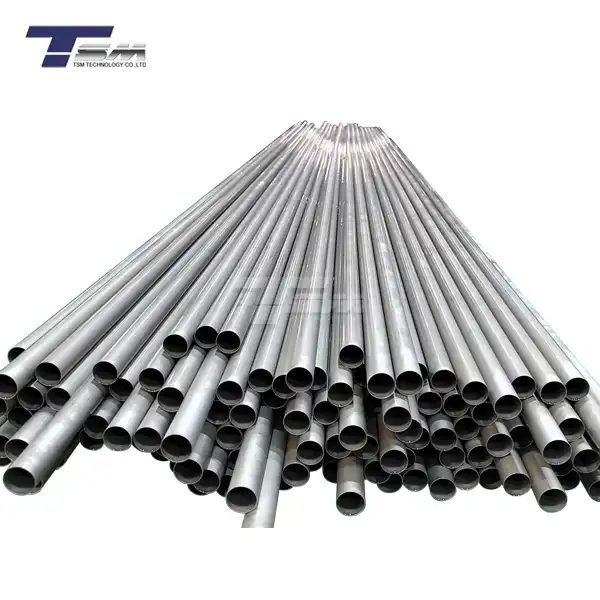

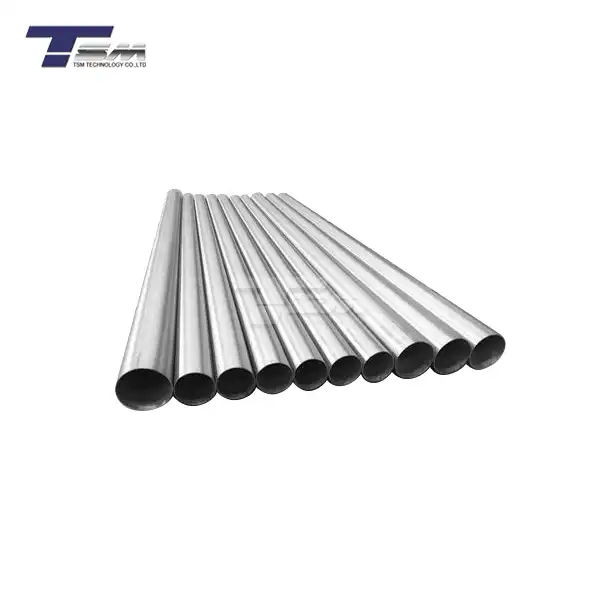

Titanium Seamless Tube

Grade: GR1/GR2/GR5/GR7/GR9/GR11/GR16/GR17

Standard: ASTM B338/ASME SB338/AMS 4928

Outside Diameter: 3.0-150 mm

Wall Thickness: 0.3-10 mm

Length: Max. 15,000mm (custom lengths available for special sizes)

Customization: Cold-rolled and hot-extruded options available for high-pressure and precision applications

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Seamless Tubes Manufacturer and Supplier

At TSM Technology Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of high-performance Titanium Seamless Tubes. Our advanced manufacturing processes and stringent quality control ensure that our products meet the most demanding industry standards. With over a decade of experience, we've established ourselves as a trusted partner for aerospace, chemical processing, and medical device manufacturers worldwide.

What are Titanium Seamless Tubes?

The Titanium Seamless Tubes are cylindrical, hollow structures made from pure titanium or titanium alloys without any welding seams. These tubes offer an exceptional combination of strength, corrosion resistance, and lightweight properties, making them ideal for critical applications in various industries.

Specifications

|

Classification |

OD(outer diameter)≤15 |

OD(outer diameter)≥15 |

|

|

WT(Wall Thickness)≤2.0 |

WT(Wall Thickness)>2.0-4.5 | ||

|

Length |

500-4000 | 500-9000 | 500-6000 |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668°C (3034°F) |

| Tensile Strength | 345-620 MPa |

| Yield Strength | 275-480 MPa |

| Elongation | 15-25% |

| Thermal Conductivity | 21.9 W/m·K |

Product Standards

- ASTM B338

- ASME SB-338

- AMS 4941/4943

Precision Manufacturing & Quality Assurance

TSM Technology's production process begins with certified raw materials, progressing through extrusion, cold working, and precision heat treatment. Final components undergo CNC machining (±0.01mm accuracy) and specialized surface treatments (anodizing/electropolishing). Our ISO 17025-certified lab verifies quality using:

NDT: Ultrasonic/X-ray testing

Composition: OES/XRF spectrometers

Microstructure: Metallographic/SEM analysis

Features of Titanium Seamless Tubes

- Exceptional corrosion resistance

- High strength-to-weight ratio

- Excellent biocompatibility

- Superior heat resistance

- Low thermal expansion

Applications

- Aerospace hydraulic systems

- Chemical processing equipment

- Oil and gas exploration

- Medical implants and devices

- Heat exchangers

- Marine engineering

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for Titanium Seamless Tubes. Our cutting-edge material technology ensures high-purity products with superior dimensional accuracy. We offer customized surface treatments like sandblasting, acid pickling, and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees compliance across all processes. We excel in providing industry-specific solutions, whether for medical implants, chemical processing equipment, or aerospace components. With strategic raw material reserves and a global supply chain, we ensure fast response times and reliable delivery, even for urgent or specialized requirements.

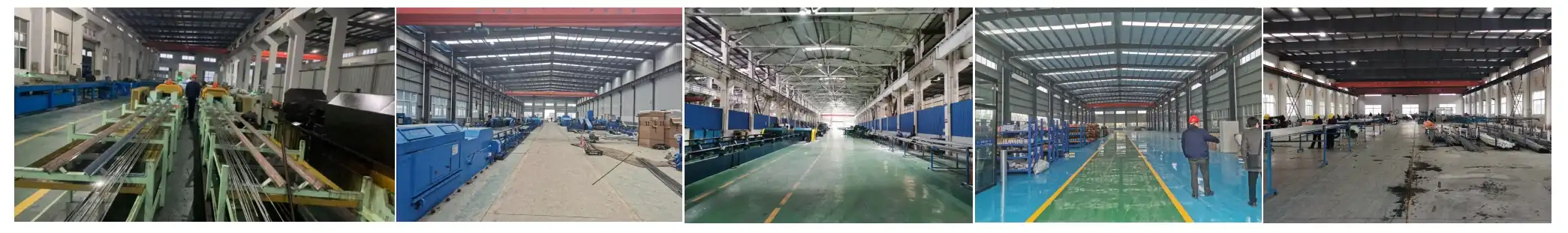

Factory

Packaging and Shipping

TSM Technology ensures secure shipment with protective coil wrapping and palletization, while offering customized packaging solutions. Our global logistics network provides both standard and express delivery options, guaranteeing timely worldwide distribution for urgent and routine orders alike.

FAQ

Q1: What grades of titanium do you offer for seamless tubes?

A1: We provide Grade 1, 2, 3, 4, 5 (Ti-6Al-4V), and 7 products.

Q2: Can you produce custom sizes of products?

A2: Yes, we offer customization services to meet specific dimensional requirements.

Q3: What is the lead time for products?

A3: Lead times vary based on specifications and quantity. Standard orders typically ship within 2-4 weeks.

Q4: Do you provide material certifications with your products?

A4: Absolutely. We provide full material traceability and test certifications with every order.

Q5: How do you ensure the quality of your products?

A5: We employ rigorous quality control measures, including NDT, chemical analysis, and mechanical testing, adhering to international standards.

Contact Us

Ready to elevate your projects with our superior Titanium Seamless Tubes?

Contact our expert team at info@tsm-technology.com for personalized assistance and quotes. Trust TSM Technology for unmatched quality, reliability, and innovation in titanium solutions.