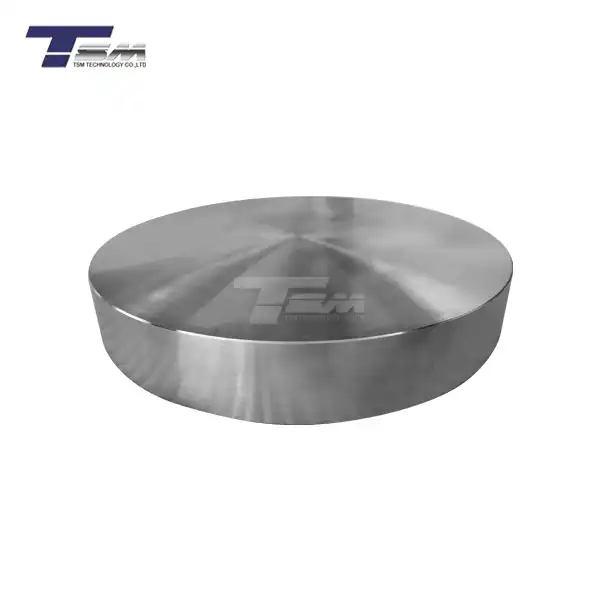

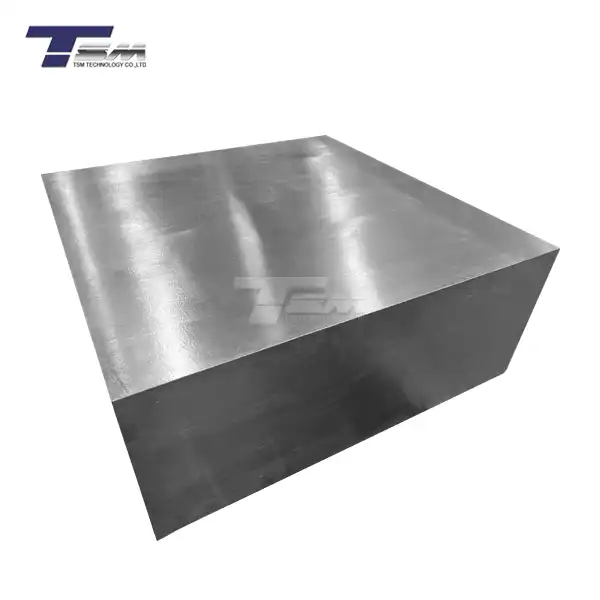

Nickel Alloy Forged Block

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: MONEL 400, INCONEL 600/625

Standard: ASTM B564

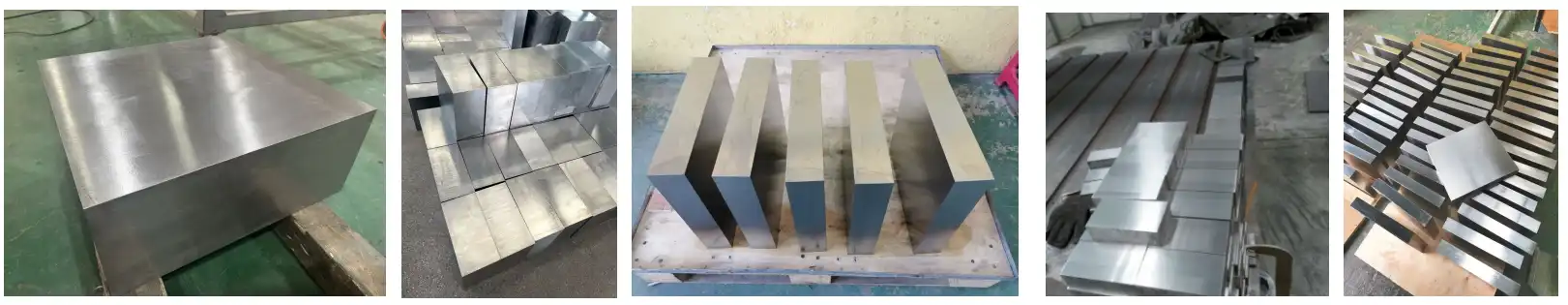

Dimensions: 100×100×100mm - 2000×2000×1000mm

Certification: EN 10204 3.1 with full traceability

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy Forged Blocks Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of premium Nickel Alloy Forged Blocks. With over 14 years of experience, we've established ourselves as a trusted partner for industries requiring high-performance materials. Our products offer superior strength, corrosion resistance, and durability for the most challenging applications.

What are Nickel Alloy Forged Blocks?

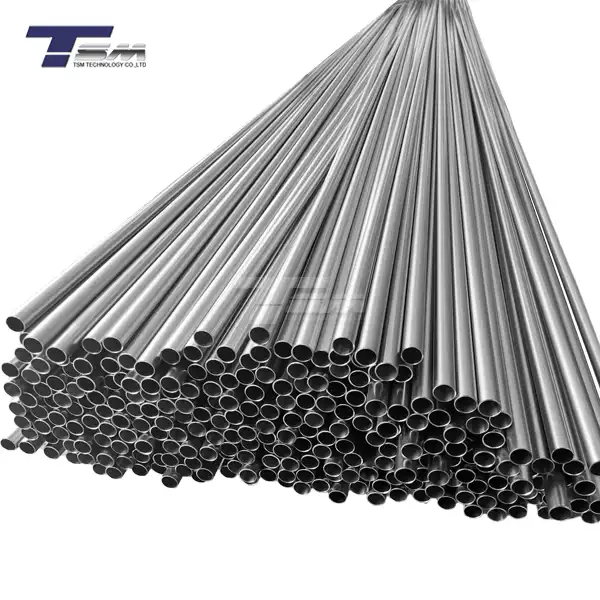

The Nickel Alloy Forged Blocks are high-strength, corrosion-resistant materials created through advanced forging processes. These blocks serve as the foundation for critical components in aerospace, oil & gas, power generation, and chemical processing industries.

Specifications

| Property | Value |

|---|---|

| Alloy Types | Inconel, Monel, Hastelloy, Incoloy |

| Size Range | 50mm - 1000mm diameter |

| Weight | Up to 5000 kg |

| Shapes | Round, square, rectangular |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550-1380 MPa |

| Yield Strength | 240-1030 MPa |

| Elongation | 20-50% |

| Hardness | 150-350 HB |

| Melting Range | 1300-1450°C |

Product Standards

Our products meet or exceed industry standards, including ASTM, ASME, and AMS specifications.

Features of Nickel Alloy Forged Blocks

- Exceptional corrosion resistance

- High-temperature strength

- Excellent fatigue resistance

- Superior machinability

- Uniform microstructure

Production Process of Nickel Alloy Forged Blocks

TSM Technology utilizes advanced forging technologies to produce high-performance nickel alloy blocks. Our process begins with rigorous material selection and testing of premium-grade nickel alloys. The billets undergo precise heating and forging using state-of-the-art open die or closed die techniques to achieve optimal grain structure.

Following forging, we implement controlled cooling processes before applying specialized heat treatment, including solution annealing and aging, to enhance mechanical properties and microstructure stability. Precision machining then brings each block to exact final dimensions.

Quality assurance is integral throughout production, with comprehensive non-destructive testing including:

- Ultrasonic inspection for internal integrity

- Dye penetrant or magnetic particle examination

- Dimensional verification to tight tolerances

This controlled manufacturing process delivers nickel alloy forged blocks with exceptional strength, corrosion resistance, and reliability for critical applications in aerospace, power generation, and chemical processing industries.

Applications

Nickel Alloy Forged Blocks find critical use in:

- Aerospace engine components

- Oil & gas valves and fittings

- Power generation turbine parts

- Chemical processing equipment

- Marine propulsion systems

Factory

Why Choose TSM Technology?

At TSM Technology, we offer unparalleled expertise in nickel alloy forging. Our advanced material technology ensures high-purity products with precise tolerance control. We provide customized surface treatments like sandblasting and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001, AS9100D, and NADCAP certifications, guarantees compliance and traceability.

We prioritize sustainable production methods and efficient resource utilization. Our industry-specific solutions cater to the medical, energy, and aerospace sectors. With a global supply chain and strategic raw material reserves, we ensure quick responses to special requirements and maintain consistent delivery performance.

Package and Shipping

TSM Technology ensures the secure transport of nickel alloy forged blocks with custom protective crating and anti-corrosion wrapping. We provide full material certification and flexible global shipping options (air/sea/express) with complete documentation for hassle-free delivery.

FAQ

Q: What is the minimum order quantity for products?

A: We offer flexible MOQs starting from 100 kg, depending on the alloy type and dimensions.

Q: Can you provide custom sizes and shapes?

A: Yes, we specialize in custom forging to meet your specific requirements.

Q: What is the typical lead time for products?

A: Standard lead times range from 4-8 weeks, with expedited options available.

Q: Do you offer material certifications?

A: Absolutely. We provide full material traceability and test reports with every order.

Q: Can TSM Technology assist with material selection?

A: Our metallurgical experts are available to help you choose the best alloy for your application.

Contact Us

Ready to elevate your projects with premium Nickel Alloy Forged Blocks? Contact TSM Technology today:

Email: info@tsm-technology.com

_1752550122066.webp)