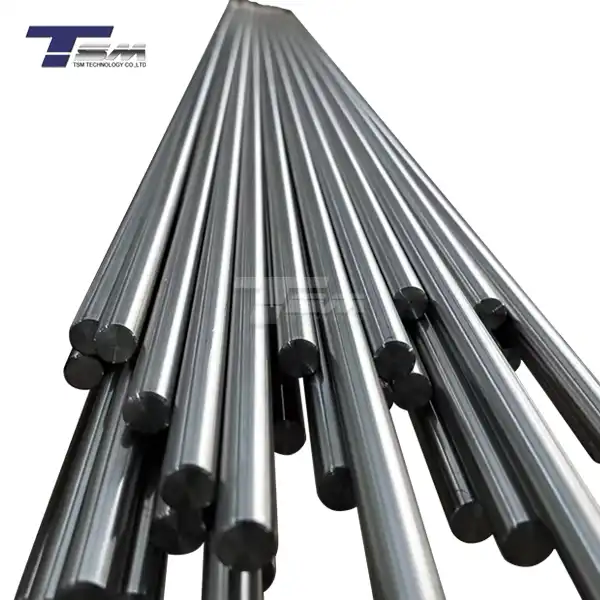

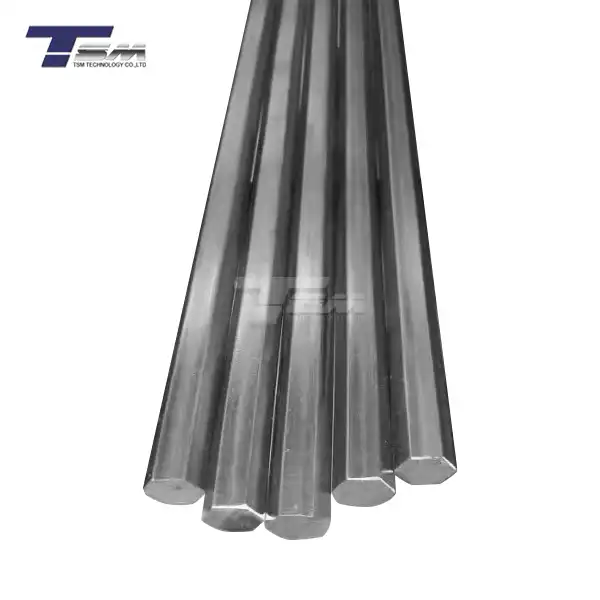

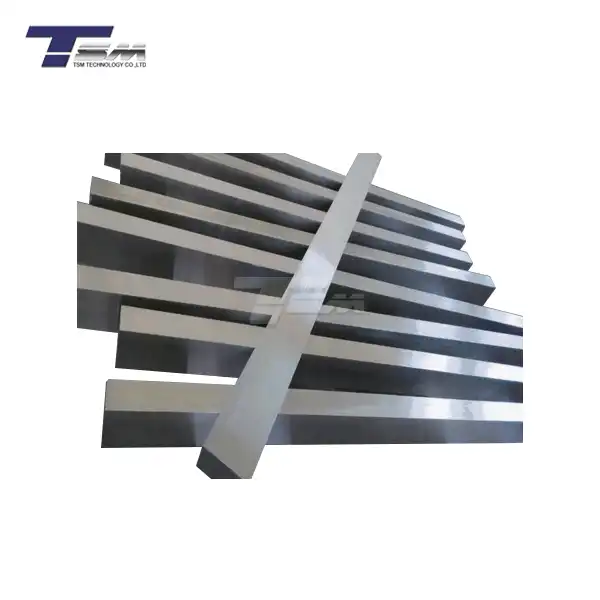

Titanium Round Bar

Supply Ability: 300 Tons/month

Grade: GR1/GR2/GR5(Ti6Al4V)/GR4/GR7/GR9/GR11/GR16/GR17

Standard: ASTM B348, AMS 4928

Diameter: 3mm - 500mm

Length: 1000mm - 6000mm (random or exact lengths)

Hot forged/cold drawn with full traceability including melt reports. Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Round Bar Manufacturer and Supplier

At TSM Technology Co., Ltd., we're proud to be a leading manufacturer and supplier of high-quality Titanium Round Bars. With over 14 years of experience in the industry, we've established ourselves as a trusted source for precision-engineered titanium products. Our products are known for their exceptional strength, corrosion resistance, and lightweight properties, making them ideal for critical applications across various industries.

What are Titanium Round Bars?

The Titanium Round Bars are cylindrical metal rods made from titanium or titanium alloys. They're prized for their excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. These properties make them essential in aerospace, medical, and industrial applications where high performance and reliability are crucial.

Specification

| Diameter | Length | Grade | Finish |

|---|---|---|---|

| 3mm - 300mm | Up to 6m | Grade 2, Grade 5 (Ti6Al4V) | Mill finish, Polished |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ (Grade 2), 4.43 g/cm³ (Grade 5) |

| Melting Point | 1665°C (Grade 2), 1604-1660°C (Grade 5) |

| Tensile Strength | 345 MPa (Grade 2), 895 MPa (Grade 5) |

| Yield Strength | 275 MPa (Grade 2), 828 MPa (Grade 5) |

Product Standards

Our products comply with international standards, including:

- ASTM B348

- AMS 4928

- ISO 5832-2 (for medical applications)

Features of Titanium Round Bars

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Excellent biocompatibility

- High temperature resistance

- Low thermal expansion

Production Process of Titanium Round Bars

TSM Technology manufactures premium titanium round bars through a precision 7-stage process. Starting with certified raw materials, we utilize advanced melting technologies (VAR/EBM) to achieve ultra-low impurity levels. The billets undergo:

- Thermo-Mechanical Processing: Hot forging/rolling for grain refinement

- Precision Machining: CNC turning to ±0.05mm tolerance

- Heat Treatment: Optimized α+β phase balance

Each bar receives:

- Ultrasonic testing for internal defects

- Laser-measured straightness (<0.1mm/m)

- Mirror polishing (Ra≤0.4μm)

Applications

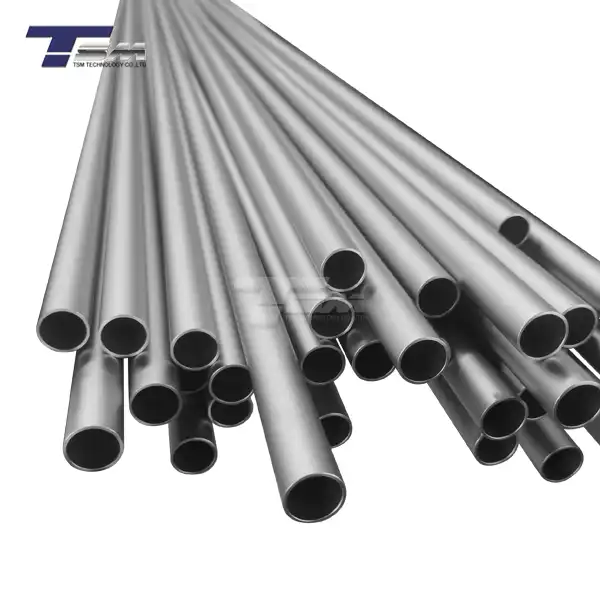

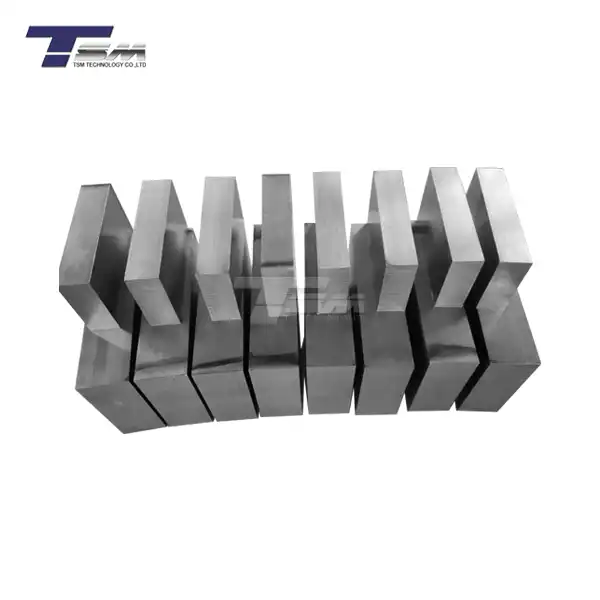

Titanium Round Bars find use in various industries:

Aerospace: Aircraft components, fasteners

Medical: Implants, surgical instruments

Marine: Propeller shafts, underwater equipment

Chemical Processing: Reactors, heat exchangers

Automotive: Racing components, exhaust systems

Quality Inspection

Our rigorous quality control process includes:

Chemical composition analysis

Mechanical property testing

Non-destructive testing (ultrasonic, eddy current)

Dimensional accuracy checks

Surface finish inspection

After placing an order, we will provide: QAC/ITP/MTR

Factory

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for products. Our advanced material technology ensures high-purity titanium with precise composition control. We offer precision manufacturing with ultra-tight tolerances and customized surface treatments, including sandblasting, acid pickling, and polishing, to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001:2015, ISO 13485:2016, AS9100D, and NADCAP certifications, ensures compliance and traceability. We're committed to sustainable production, utilizing green manufacturing processes and efficient material recycling. Our industry-specific solutions, rapid response to special requirements, and global supply chain ensure we meet diverse needs in the medical, energy, chemical, and aerospace sectors. With strategic raw material reserves and smart logistics, we provide unparalleled reliability and service in titanium supply.

Package and Shipping

FAQ

- Q: What grades of titanium do you offer for round bars?

A: We primarily offer Grade 2 (commercially pure) and Grade 5 (Ti6Al4V) products. - Q: Can you provide custom diameters and lengths?

A: Yes, we can customize products to your specific requirements. - Q: What is the lead time for custom orders?

A: Lead times vary based on specifications, but typically range from 2-6 weeks. - Q: Do you offer material certifications?

A: Yes, we provide full material certifications and test reports with every order. - Q: Are your titanium products suitable for medical implants?

A: Yes, our medical-grade titanium meets ISO 5832-2 standards for implantable devices.

Contact Us

Ready to order or have questions about our Titanium Round Bars? We're here to help!

Email: info@tsm-technology.com