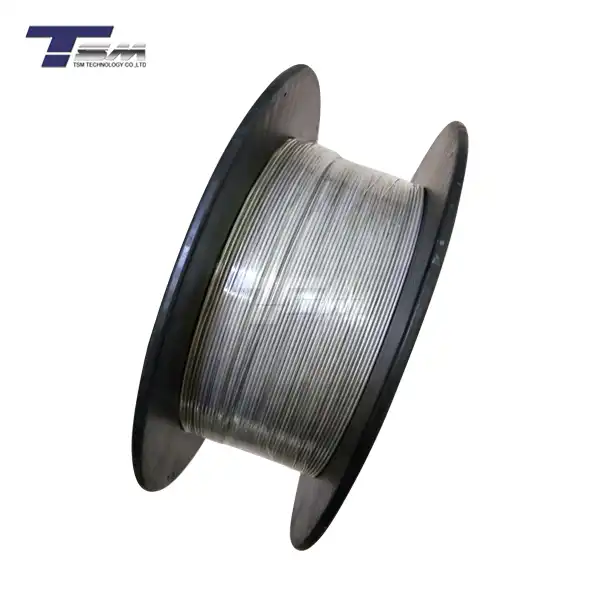

Titanium Wire Coil

Supply Ability: 300 Tons/month

Grade: GR1/GR2/GR3/GR4/GR7/GR9/GR11/GR16/GR23

Diameter: 0.1mm - 6.0mm

Packaging: 1kg - 50kg spools

Annealed with ≤0.005mm ovality

Surface treatments: sandblasting/anodizing

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

TSM Technology: Your Trusted Titanium Wire Coil Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of premium Titanium Wire Coil. With 14 years of expertise in superior alloys, we deliver top-quality titanium products to precision engineering industries worldwide. Our advanced processing techniques and rigorous quality control ensure that our products meet the highest standards for aerospace, medical, and industrial applications.

What are Titanium Wire Coils?

The Titanium Wire Coils are continuous lengths of titanium wire wound into compact, cylindrical shapes. These versatile components offer an excellent combination of strength, corrosion resistance, and lightweight properties. Our products are ideal for various high-performance applications across multiple industries.

Specifications

| Property | Value |

|---|---|

| Diameter Range | 0.1mm - 10mm |

| Grade Options | Grade 1, 2, 3, 4, 5 (Ti-6Al-4V) |

| Coil Weight | 5kg - 500kg |

| Surface Finish | Bright, Matte, Polished |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668°C (3034°F) |

| Tensile Strength | 240-1100 MPa (varies by grade) |

| Yield Strength | 170-1000 MPa (varies by grade) |

| Elongation | 15-54% (varies by grade) |

Product Standards

Our Titanium Wire Coils comply with international standards, including:

- ASTM B863

- AMS 4967

- ISO 5832-2 (for medical applications)

Features of Titanium Wire Coil

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Biocompatibility for medical applications

- High temperature performance

- Excellent fatigue resistance

Quality Inspection

Our rigorous quality control process includes:

- Material composition analysis

- Dimensional checks

- Mechanical property testing

- Surface quality inspection

- Non-destructive testing (NDT) for critical applications

Applications

- Aerospace: Fasteners, springs, and structural components

- Medical: Surgical implants, dental devices, and prosthetics

- Chemical Processing: Heat exchangers and reactor components

- Marine: Offshore structures and subsea equipment

- Automotive: High-performance engine parts and exhaust systems

- Additive Manufacturing: Wire-fed 3D printing processes

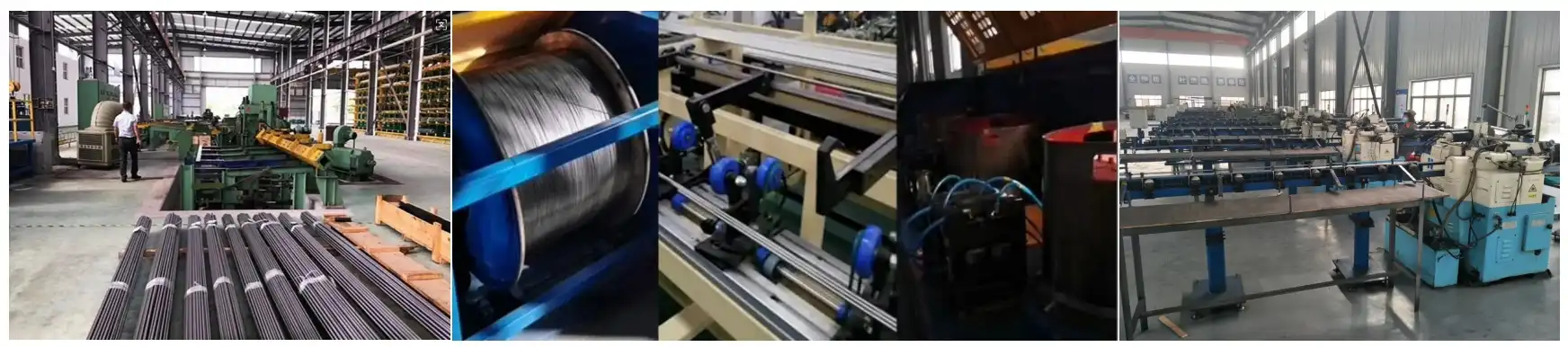

Production and Processing Technology

TSM Technology utilizes state-of-the-art equipment and advanced techniques to produce high-quality products:

- Raw material selection and testing

- Wire drawing to achieve precise diameters

- Heat treatment for optimal mechanical properties

- Surface finishing (if required)

- Coiling and packaging

Factory

Why Choose TSM Technology?

TSM Technology stands out as your premier product supplier due to our cutting-edge material technology and purity control. We excel in precision manufacturing, offering ultra-tight tolerances and customized surface treatments like sandblasting and acid pickling. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, ensures full traceability and compliance. We prioritize sustainable production methods and provide tailored solutions for medical, energy, and aerospace sectors. With rapid response capabilities, global supply chain support, and strategic raw material reserves, TSM Technology delivers unparalleled value and reliability to our partners worldwide.

Package and Shipping

TSM Technology ensures secure transport with protective-wrapped spools/coils or sturdy wooden crates. Custom packaging solutions are available. We provide global logistics support and customs clearance for seamless worldwide delivery.

FAQ

Q: What is the minimum order quantity for products?

A: Our MOQ varies based on wire diameter and grade. Please get in touch with us for specific quotations.

Q: Can you provide material certificates with each order?

A: Yes, we provide full material test reports (MTRs) with every shipment.

Q: What is the lead time for product orders?

A: Typical lead times range from 2-4 weeks, depending on specifications and quantity.

Q: Do you offer custom alloy compositions for products?

A: Yes, we can develop custom titanium alloys to meet specific performance requirements.

Q: How do you ensure the consistency of product properties across batches?

A: We maintain strict process controls and perform regular quality checks to ensure batch-to-batch consistency.

Contact Us

Ready to elevate your projects with high-quality Titanium Wire Coils? Contact TSM Technology today for expert advice and quotations:

Email: info@tsm-technology.com