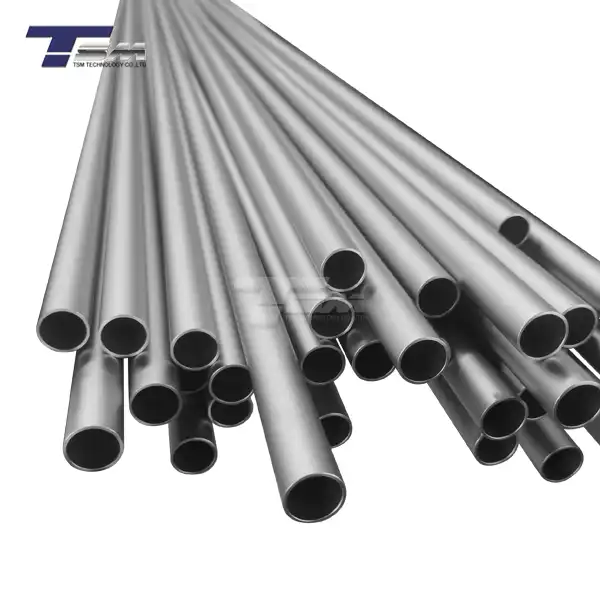

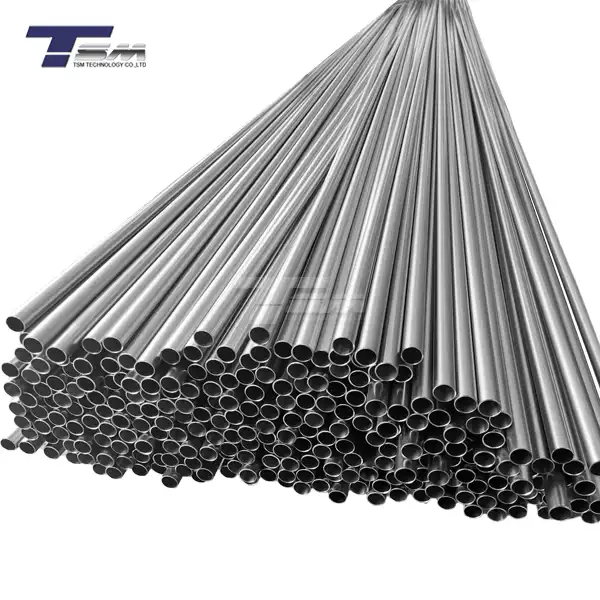

Nickel Alloy Welded Pipe

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade:Nickel 201/200,Monel K500/400,Inconel 600/625

Standard: ASTM B705 / B775 / ASME SB705

OD Range: 10mm - 1200mm

Wall Thickness: 1.0mm - 30mm

Process: Automatic TIG welded with full NDE testing

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy Welded Pipe Manufacturer and Supplier

At TSM Technology Co., Ltd., we're proud to be a leading manufacturer and supplier of high-quality Nickel Alloy Welded Pipe. With over 14 years of experience, we've built a reputation for innovation, reliability, and excellence in the superior nickel alloy industry. Our product offers unparalleled corrosion resistance, strength, and durability, making it the ideal choice for critical applications in oil & gas, chemical processing, and aerospace sectors.

What are Nickel Alloy Welded Pipes?

The Nickel Alloy Welded Pipes are premium piping solutions crafted from advanced nickel-based alloys. These pipes combine exceptional mechanical properties with superior corrosion resistance, making them ideal for harsh environments and high-temperature applications.

Specifications

| Property | Value |

|---|---|

| Diameter Range | 1/8" to 24" |

| Wall Thickness | Schedule 5S to XXS |

| Length | Up to 12 meters |

| Surface Finish | Pickled, Bright Annealed |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550-1100 MPa |

| Yield Strength | 240-760 MPa |

| Elongation | 30-60% |

| Hardness | 80-35 HRC |

Product Standards

Our product complies with international standards including:

- ASTM B725, B619, B622

- ASME SB-725, SB-619, SB-622

- DIN 17750, 17751

- NACE MR0175/ISO 15156

Production and Processing Technology

TSM Technology utilizes state-of-the-art welding technologies including TIG (Tungsten Inert Gas) welding, plasma welding and laser welding to produce premium nickel alloy pipes. Our comprehensive production process begins with strict material selection and quality inspection, followed by precision cutting and forming. The welding process is enhanced by advanced heat treatment to ensure optimal material properties.

Our integrated manufacturing system ensures:

✓ Precise dimensional control (±0.1mm tolerance)

✓ Superior surface finish (Ra≤0.8μm)

✓ Consistent weld integrity

✓ Full traceability from raw material to finished product

Quality Inspection

We maintain rigorous quality control measures:

- 100% visual inspection

- Hydrostatic testing

- Ultrasonic testing

- Radiographic examination

- Positive Material Identification (PMI)

Features of Nickel Alloy Welded Pipe

- Exceptional corrosion resistance in aggressive media

- High strength-to-weight ratio

- Excellent high-temperature performance

- Superior weldability and formability

- Resistance to stress corrosion cracking

Applications

Nickel Alloy Welded Pipe finds extensive use in:

- Oil and gas exploration and production

- Chemical and petrochemical processing

- Power generation plants

- Aerospace and defense industries

- Marine and offshore installations

Factory

Why Choose TSM Technology?

TSM Technology stands out as your preferred partner for the product due to our cutting-edge material technology and purity control. We offer precision manufacturing with ultra-tight tolerances and customized surface treatments. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, ensures full traceability. We excel in sustainable production, utilizing green manufacturing processes and efficient resource management. Our industry-specific solutions cater to the medical, energy, and aerospace sectors, supported by rapid response capabilities. With a global supply chain and strategic raw material reserves, we guarantee reliable delivery and consistent quality for all your nickel alloy needs.

Package and Shipping

TSM Technology provides customized packaging solutions with protective wrapping and reinforced crating for optimal product safety. Our global logistics network offers flexible shipping options, including express air freight for urgent orders, ensuring timely worldwide delivery with real-time tracking.

FAQ

- Q: What is the minimum order quantity for the product?

A: Our MOQ is typically 100 meters, but we can accommodate smaller orders for specialized requirements. - Q: Can you provide material certificates?

A: Yes, we provide full material traceability and certificates (MTR) with every order. - Q: What is the typical lead time for the product?

A: Standard lead times are 4-6 weeks, but this can vary based on specifications and quantity. - Q: Do you offer custom sizes or alloy compositions?

A: Absolutely! We specialize in custom solutions to meet your specific project needs. - Q: How do you ensure the quality of your product?

A: We employ rigorous quality control measures throughout production, including advanced NDT techniques and final inspections.

Contact Us

Ready to elevate your project with our superior Nickel Alloy Welded Pipe? Contact our expert team today for personalized support and quotations.

Email: info@tsm-technology.com