Washers

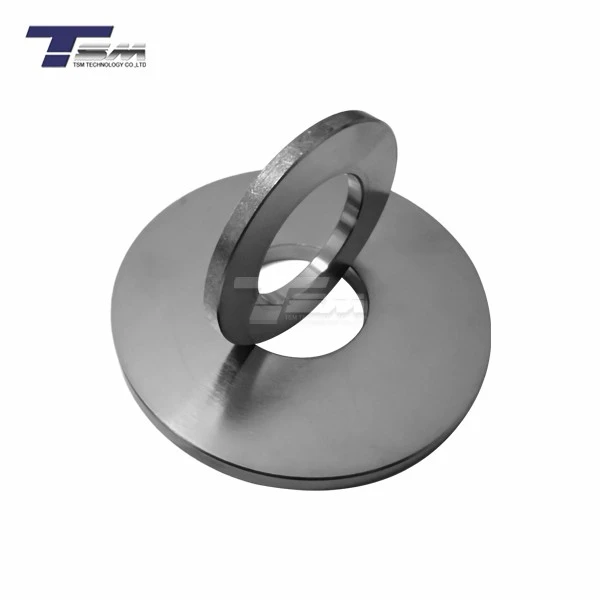

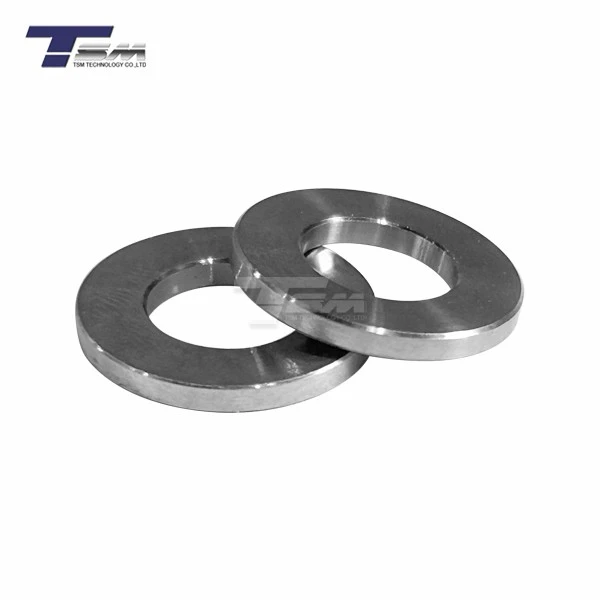

TSM Fasteners Washers for Critical Applications

At TSM Technology, we manufacture high-performance washers designed to enhance fastener reliability, distribute load, and prevent loosening in demanding environments. Our washers are crafted from premium materials, including titanium, nickel alloys(Monel, Inconel, Incoloy, and Hastelloy), Copper and Aluminum alloy. Leveraging decades of metallurgical expertise, our precision fastening components deliver critical strength and corrosion resistance for demanding applications in aerospace, energy, chemical processing, and advanced manufacturing. Rigorously tested to comply with international standards (ASTM/ASME, EN, DIN, JIS, GOST), TSM washers provide reliable performance in harsh environments.

Product Standards and Available Materials Selection

| Material Category | Available Grades | Standards | Typical Applications |

|---|---|---|---|

| Titanium | Grade 1, 2, 3, 4, 5,7, 9, 12 |

DIN912 |

Aerospace fasteners, marine hardware, medical implants |

| Nickel Alloys |

Inconel601 |

Chemical processing, oil & gas equipment, nuclear reactors |

|

| HastelloyC22 HastellayC276 |

|||

| Aluminum | 6061-T6, 7075-T6 | Aircraft structures, lightweight industrial fasteners |

|

| Copper Alloys | C11000, C36000 | Electrical components, plumbing systems, marine hardware |

- Other standard or non-standard bolts can be customized.

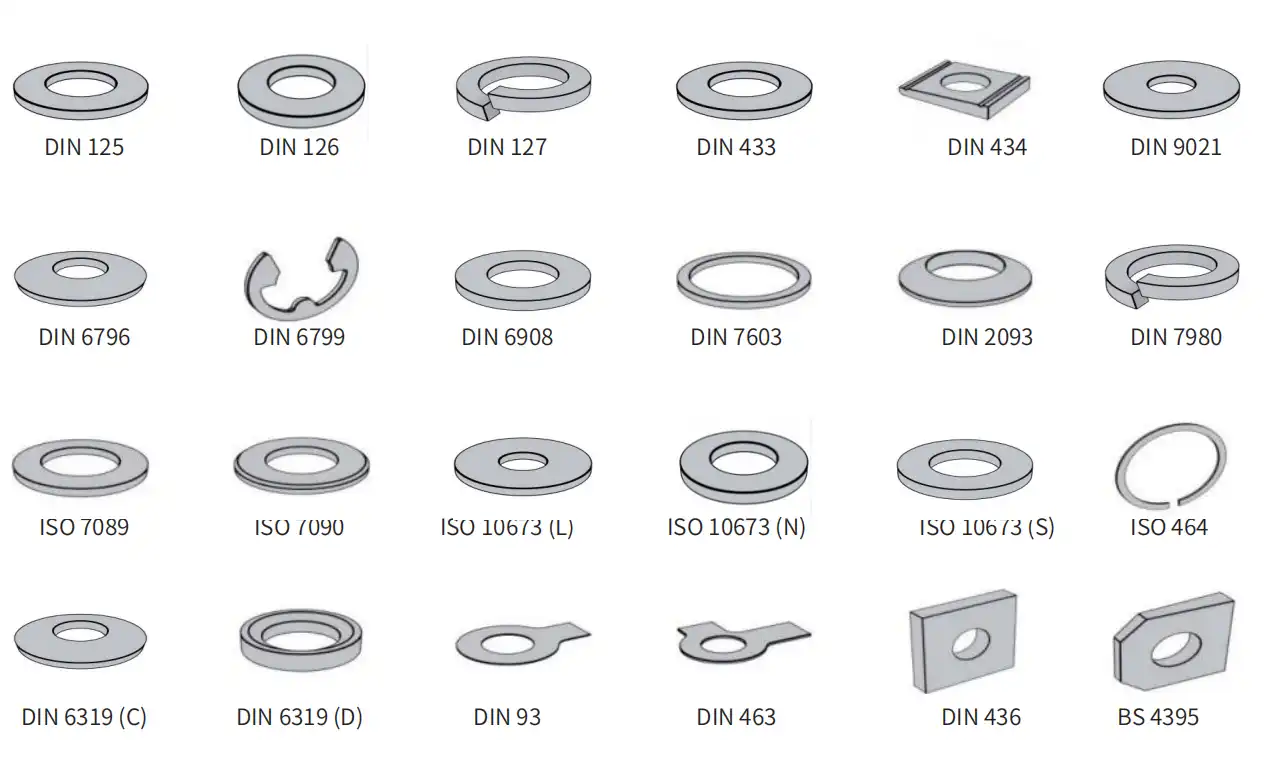

Washers Types

|

Type |

Disc Spring |

Thrust Washers |

Plain Washer |

Spring Lock Washers |

Toothed Lock Washers |

|

Square Washers |

Beveled Washers |

Beveled Washers |

Tab Washers |

Tab Washers |

|

|

Available Size: |

M1-M64 |

||||

To learn more about TSM fasteners, please visit our fasteners website.

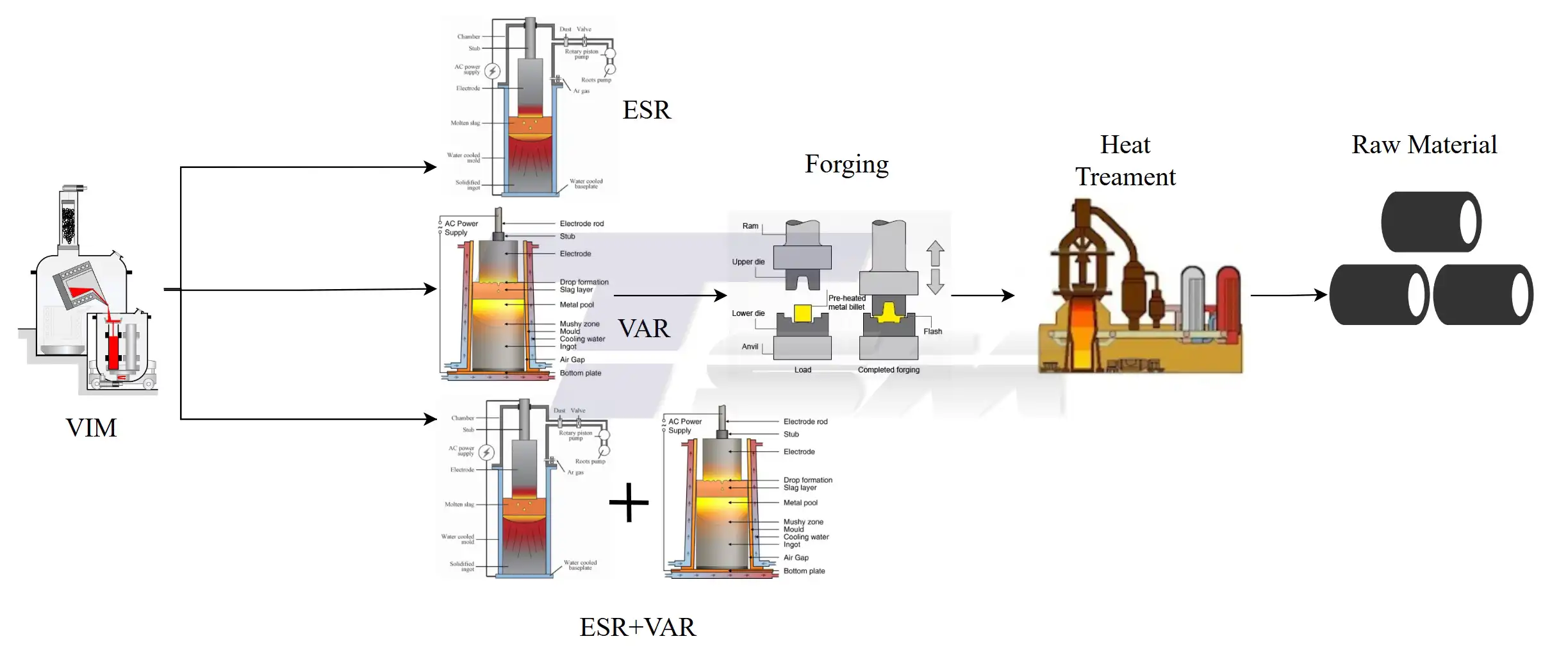

Key Processes

Cold forging for superior grain structure (up to M36 size)

Rolled threads (vs. cut) for 30% higher fatigue life

Passivation & coatings – Xylan® for friction control, Ni-PTFE for chemical resistance

Raw Material Processes

Quality Assurance

Material Certifications: Mill test reports per EN 10204 3.1

Dimensional Checks: Optical comparators for thread pitch/diameter verification

Mechanical Testing: Tensile, hardness (Rockwell C), and Charpy impact tests

NDT: Eddy current testing for surface defects

Industry-Specific Washer Solutions

Aerospace & Defense

Our precision ring-rolled washers (±0.5mm tolerance) are engineered for jet engine mounts and landing gear systems. Manufactured with flight-critical ASME Sec VIII compliant RT/PT testing to ensure zero-defect performance in extreme operating conditions.

Oil & Gas

High-pressure washers (±0.5mm) maintain seal integrity in valves and flanges up to 20,000 PSI. Full ASTM E1742 compliant PT/RT testing prevents failure in offshore drilling and refining applications.

Power Generation

Die-forged turbine washers (±0.8mm) provide vibration-resistant fastening in nuclear and thermal plants. UT testing detects flaws ≥0.8mm to ensure long-term stability under thermal cycling.

Marine Engineering

Corrosion-resistant washers (±1.5mm) withstand harsh saltwater environments for hull assemblies and subsea pipelines. ASME Sec VIII compliant PT testing verifies integrity for permanent underwater installations.

Heavy Construction

Structural-grade washers (±1.5mm) reinforce seismic bracing and suspension bridges. Comprehensive UT/RT testing validates load-bearing capacity for skyscrapers and heavy equipment.

Why Choose TSM Washers?

Quaerimus socium cooperantem ad res nostras dilatandas.

High-Volume Washer Production Consistency

Die forging delivers ±0.8mm tolerance for batch orders (1M+ units). Optimized for automotive/industrial fasteners, reducing rework and ensuring interchangeability.

Precision Manufacturing & Quality Assurance

TSM washers are precision CNC-machined to ±0.05mm tolerances, with surface treatments like anodizing and Xylan® coatings for durability. Each undergoes rigorous dimensional, hardness, and salt spray testing to ensure reliability in extreme conditions.

Full Certification

TSM washers meet the highest industry standards with full EN 10204 3.1/3.2 material certifications, ASTM F436 mechanical compliance, and DIN specifications. Our complete traceability system tracks each washer from raw material to final inspection, ensuring documented quality for critical applications.

Oversized & Corrosion-Resistant Washers

Free forging produces large washers (±1.5mm) for marine/oil platforms. Combined with PT/RT testing, they resist saltwater, chemicals, and extreme stress.

Zero-Defect Guarantee via Rigorous Testing

UT detects flaws ≥0.8mm; RT meets ASTM E1742; PT complies with ASME Section VIII. Eliminate failure risks in corrosive or load-intensive environments.

Precision-Formed Washers for Critical Applications

Ring rolling achieves ±0.5mm tolerance in pressure vessel washers. Free/die forging adapts to special shapes (±0.8–1.5mm), ideal for seismic or high-pressure systems.

Production and Packaging

FAQ

Q: What tolerance is achievable for pressure vessel Washers via ring rolling?

A: Ring-rolled Fasteners Washers achieve ±0.5mm tolerance, ideal for high-pressure systems. RT/PT testing ensures ASME/ASTM compliance.

Q: Can you produce high-volume batch Washers with tight tolerances?

A: Yes. Die forging delivers ±0.8mm tolerance for mass-produced Fasteners Washers (e.g., automotive/industrial), with UT flaw detection.

Q: Are oversized/custom Washers possible for marine applications?

A: Free forging makes large, corrosion-resistant Fasteners Washers (±1.5mm). PT/UT testing meets ASME Section VIII for saltwater environments.

Q: How do you guarantee zero defects in critical Washers?

A: UT detects flaws ≥0.8mm; RT follows ASTM E1742; PT complies with ASME Sec VIII – triple-tested reliability.

Q: Do your pressure vessel Washers meet ASME standards?

A: Absolutely. Ring-rolled washers (±0.5mm) undergo RT/PT per ASME Sec VIII for boilers, reactors, and pipelines.

Contact Us

For inquiries or custom orders about Washers, contact us today!

Email:info@tsm-technology.com

- 1