Titanium Plate

Supply Ability: 300 Tons/month

Grade: GR1/GR2/GR5/GR7/GR9/GR11/GR12/GR16/GR17

Standard: ASTM B265, ASME SB265, AMS 4911

Thickness: 0.5mm - 150mm

Width: 500mm - 3000mm

Length: 1000mm - 6000mm (custom lengths available)

Special surface finishes (mill, polished, blasted) and ultrasonic testing are available.

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Plate Manufacturer and Supplier

Welcome to TSM Technology Co., Ltd., your trusted manufacturer and supplier of premium Titanium plates. With over 14 years of experience, we specialize in delivering top-quality titanium products to meet the exacting needs of industries worldwide. Our product offerings combine superior strength, corrosion resistance, and lightweight properties, making them ideal for aerospace, medical, chemical processing, and marine applications.

What are Titanium Plates?

The Titanium Plates are flat-rolled products made from titanium alloys, known for their exceptional strength-to-weight ratio and corrosion resistance. These versatile materials are crucial in various high-performance applications where traditional metals fall short.

Specification

| Parameter | Details |

|---|---|

| Common Grades | Gr1 (TA1) /Gr2 (TA2)/Gr5 (Ti6Al4V, TC4) /Gr7 (TA9) /Gr12 (TA10) |

| Standards |

|

| Thickness Range |

|

| Width & Length |

|

| Surface Finish |

|

| Temperature Range |

|

Comparison of Common Titanium Grades

| Grade | Composition | Tensile Strength (MPa) | Key Features | Typical Uses |

|---|---|---|---|---|

| Gr1 | 99.5% Ti | 240-370 | Best ductility, corrosion resistance | Chemical linings, seawater pipes |

| Gr2 | 99.2% Ti | 345-480 | Balanced strength & formability | Heat exchangers, marine hardware |

| Gr5 | Ti-6Al-4V | 895-1000 | Highest strength, heat resistant | Aircraft parts, biomedical implants |

| Gr7 | Ti-0.2% Pd | 345-480 | Superior acid resistance | HCl/H2SO4 environments |

| Gr12 | Ti-0.3Mo-0.8Ni | 480-620 | Enhanced weldability | Petrochemical equipment |

Features of the Titanium Plate

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- High temperature performance

- Biocompatibility

- Low thermal expansion

Applications

- Aerospace structures

- Medical implants and devices

- Chemical processing equipment

- Marine components

- Heat exchangers

- Automotive parts

Physical and Chemical Properties

| Property | Value (Typical) | Comparison with Steel | Significance |

|---|---|---|---|

|

Physical Properties |

|||

|

Density |

4.51 g/cm³ | 60% of steel’s density | Lightweight for aerospace/marine apps |

|

Melting Point |

1,668°C (3,034°F) | Higher than steel (~1,500°C) | Suitable for high-temp environments |

|

Thermal Conductivity |

21.9 W/m·K | ~1/4 of steel | Poor conductor; requires heat management |

|

Electrical Resistivity |

420 nΩ·m | 5× higher than steel | Used in electrolytic/corrosive setups |

|

Elastic Modulus |

110 GPa | ~50% of steel | More flexible under stress |

|

Coeff. of Thermal Expansion |

8.6 µm/m·°C | Similar to stainless steel | Minimal warping in temp fluctuations |

|

Chemical Properties |

|||

|

Corrosion Resistance |

Forms passive oxide (TiO₂) layer; resists: • Seawater • Chlorides • Acids (e.g., HNO₃, HCl dil.) |

Ideal for marine, chemical, and medical fields | |

|

Oxidation |

Stable in air up to 600°C; beyond 800°C, forms brittle scale | Limits high-temp use without coatings | |

|

Reactivity |

Reacts with O₂/N₂/H₂ above 400°C; embrittles if contaminated during welding | Requires inert-gas shielding (Argon) | |

|

Biocompatibility |

Non-toxic; integrates with human tissue (Osseointegration) | Preferred for implants and surgical tools | |

|

Hydrogen Embrittlement |

Absorbs H₂ at >80°C; reduces ductility |

Avoid acidic/electroplating |

|

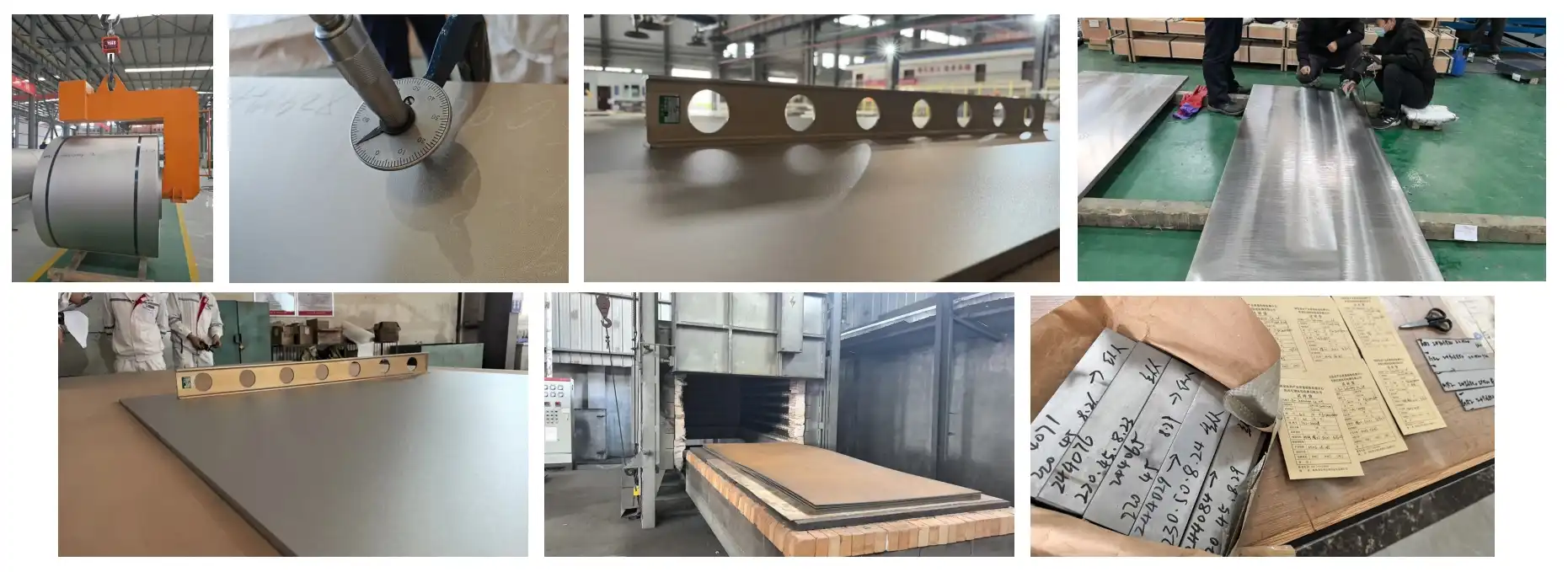

Production Process of Titanium Plate

From premium raw material selection to final finishing, our titanium plates undergo strict quality control: vacuum melting forms high-purity ingots, followed by precision hot/cold rolling, optimized heat treatment, and surface finishing (pickling/polishing) to ensure superior mechanical properties and corrosion resistance.

Quality Inspection

Our titanium plates undergo rigorous QC: XRF ensures precise composition; ultrasonic testing detects internal flaws; tensile/hardness tests verify strength; and dimensional checks confirm accuracy. Every step guarantees compliance with ASTM/ISO standards for reliability.

After placing an order, we will provide: QAC/ITP/MTR

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for the product due to our cutting-edge material technology and purity control, ensuring high-grade products. Our precision manufacturing capabilities deliver ultra-tight tolerances and customized surface treatments, perfectly suited for biomedical and chemical industry needs. We maintain comprehensive quality assurance systems, holding ISO 9001/13485, AS9100D, and NADCAP certifications. Our commitment to traceability, sustainable production, and industry-specific solutions sets us apart. With rapid response times, global supply chain resilience, and strategic raw material reserves, we're equipped to meet your most demanding titanium requirements efficiently and reliably.

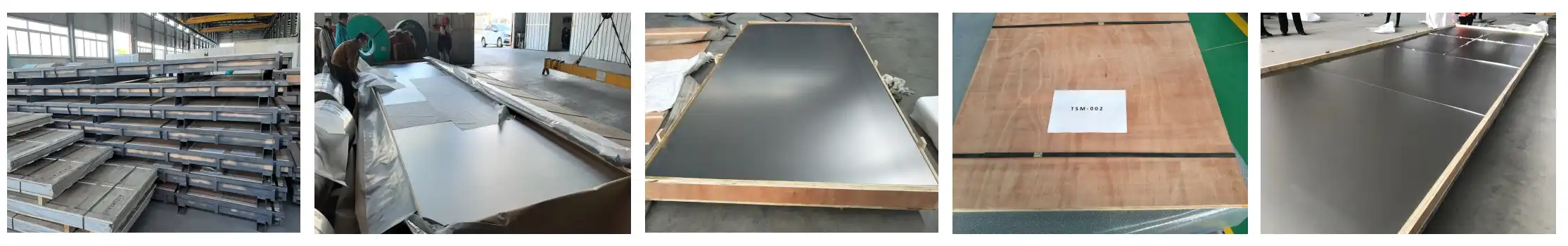

Package and Shipping

We provide custom protective packaging to ensure damage-free transit, global logistics support with expedited shipping options, and complete documentation with full traceability for every titanium plate shipment, guaranteeing safe, timely delivery worldwide.

FAQ

- Q: What is the minimum order quantity for products?

A: Our minimum order quantity varies based on grade and dimensions. Please contact us for specific requirements. - Q: Can you provide custom-cut products?

A: Yes, we offer custom cutting services to meet your exact specifications. - Q: What is the lead time for the product orders?

A: Standard lead times range from 2-6 weeks, depending on the product and quantity. Rush orders may be accommodated upon request. - Q: Do you provide material certifications with your product?

A: Absolutely. We provide full material certifications and test reports with every order. - Q: Are your products suitable for medical implants?

A: Yes, we offer medical-grade products that comply with ASTM F67 and ISO 5832-2 standards for implantable devices.

Contact Us

For inquiries or to request a quote for our premium Titanium Plate, please reach out to us:

Email: info@tsm-technology.com

_1752550122066.webp)