Providing Ultra-low Impurity Titanium Solutions for Indian Special Alloy Equipment Manufacturers

2023-06-07

Customer Background

Customer C: India's leading manufacturer of special alloy equipment, serving medium and large projects in the chemical and energy fields, with 20 years of industry experience. Its pressure vessel design has been adopted as a standard solution by many local petrochemical companies.

Cooperation status: TSM certified strategic supplier (cooperation for 3 years+)

Project Challenges

1. Core pain points:

A multinational chemical project undertaken by the customer requires titanium materials with hydrogen content ≤50ppm and iron content ≤0.15% (far exceeding the ASTM B348 standard)

The traditional supplier's products had hydrogen embrittlement cracks during welding, resulting in delayed equipment acceptance

2. Technical difficulties:

The raw materials of titanium sponge need to be screened for high-quality batches with an oxygen content of ≤ 800 ppm

Control of hydrogen during vacuum melting

Avoid iron pollution in subsequent hot processing

TSM customized solution

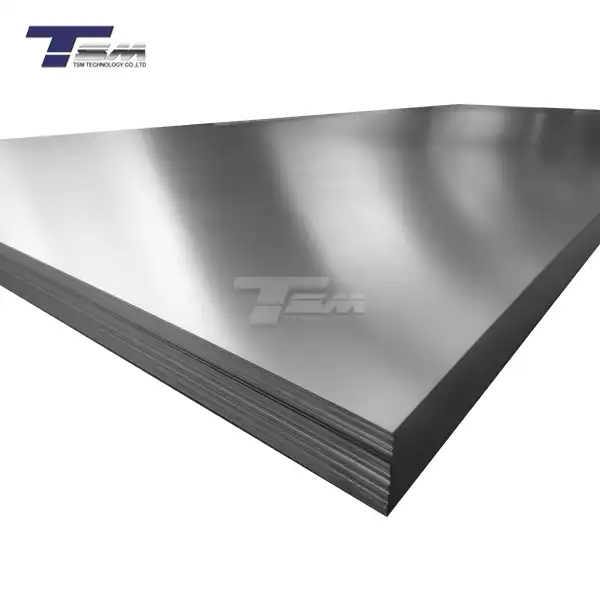

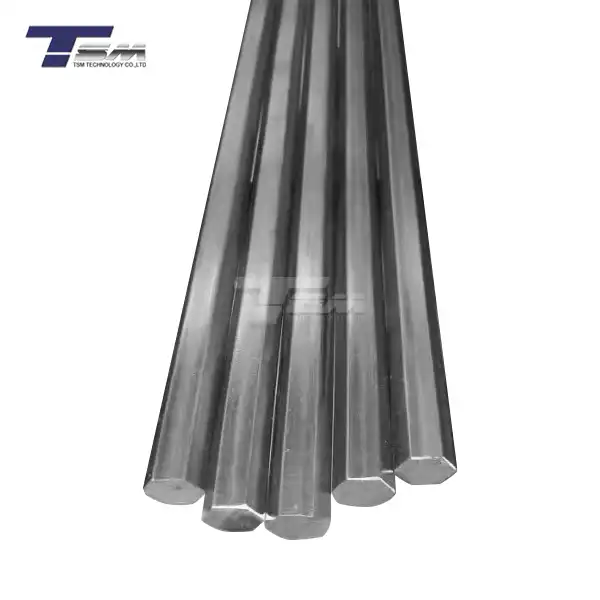

1. Product: TA2 grade titanium plate

2. Source control:

- Ukrainian grade 0 titanium sponge (measured hydrogen 32ppm/iron 0.08%)

- Special graphite crucible smelting to avoid iron pollution

3. Process innovation:

Double vacuum melting (VAR+EB furnace)

Add β-phase solution treatment after rolling

4. Full-process detection:

Spectral analysis every 50mm length (measured hydrogen content 45ppm±3)

Third-party SGS report confirms iron content of 0.12%

Delivery highlights

Only 28 days from order receipt to first batch delivery (industry average 45 days)

Provide a smelting process video for customer supervision

Customer evaluation

"TSM's metallurgical experts discovered the key points of hydrogen control even earlier than we did, and their technical memorandum has become training material for our new employees."

——C Customer Purchasing Director (excerpt from email content)

Delivery documents:

SGS test report key page

Packing list shows net weight of 2.8 tons (amount: $22k)

Why is this case worth paying attention to?

This solution demonstrates TSM's three core capabilities under extreme material requirements:

- Global resource network for raw material screening

- Know-how of special smelting processes

- System for transparent management of test data