Titanium Concentric

Standard: ASTM B363, ASME B16.9

Size: 1/2" - 48" NB

Schedule: SCH 5S to SCH 80S

Butt-weld ends with PMI (Positive Material Identification) reports.

TSM Technology: Your Premier Titanium Concentric Manufacturer and Supplier

At TSM Technology Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of premium Titanium Concentric products. With over 14 years of experience, we've established ourselves as innovators in the field of superior alloys. Our product offerings stand out for their exceptional quality, precision engineering, and versatility across various industries.

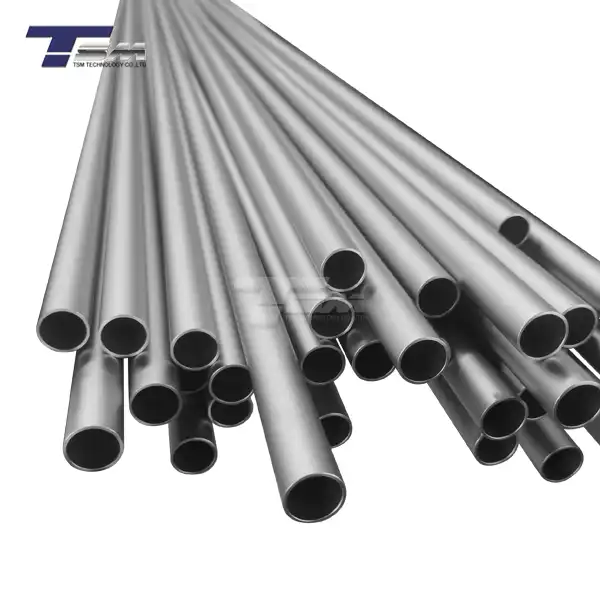

What are Titanium Concentric Products?

The Titanium Concentrics are precision-engineered components made from high-grade titanium alloys. These products feature concentric designs, offering superior strength-to-weight ratios and excellent corrosion resistance. Our range includes tubes, fittings, and valves, tailored for demanding applications in aerospace, medical, and industrial sectors.

Specifications

| Property | Value Range |

|---|---|

| Diameter | 0.5mm - 500mm |

| Wall Thickness | 0.1mm - 50mm |

| Length | Up to 6 meters |

| Surface Finish | Ra 0.2 - 3.2 μm |

Details of the titanium reducer

| NPS | DN | Large End | Small End | End to End(H) | NPS | DN | Large End | Small End | End to End(H) | NPS | DN | Large End | Small End | End to End(H) |

| 3/4*1/2 | 20*15 | 26.7 | 21.3 | 38 | 3 1/2*3 | 90*80 | 101.6 | 88.9 | 102 | 10*8 | 250*200 | 273 | 219.1 | 178 |

| 3/4*3/8 | 20*10 | 26.7 | 17.3 | 38 | 3 1/2*2 1/2 | 90*65 | 101.6 | 73 | 102 | 10*6 | 250*150 | 273 | 168.3 | 178 |

| 3 1/2*2 | 90*50 | 101.6 | 60.3 | 102 | 10*5 | 250*125 | 273 | 141.3 | 178 | |||||

| 1*3/4 | 25*20 | 33.4 | 26.7 | 51 | 3 1/2*1 1/2 | 90*40 | 101.6 | 48.3 | 102 | 10*4 | 250*100 | 273 | 114.3 | 178 |

| 1*1/2 | 25*15 | 33.4 | 21.3 | 51 | 3 1/2*1 1/4 | 9032 | 101.6 | 42.2 | 102 | |||||

| 1 1/4*1 | 32*25 | 42.2 | 33.4 | 51 | 12*10 | 300*250 | 323.8 | 273 | 203 | |||||

| 1 1/4*3/4 | 32*20 | 42.2 | 26.7 | 51 | 4*3 1/2 | 100*90 | 114.3 | 101.6 | 102 | 12*8 | 300*200 | 323.8 | 219.1 | 203 |

| 1 1/4*1/2 | 32*15 | 42.2 | 21.3 | 51 | 4*3 | 100*80 | 114.3 | 88.9 | 102 | 12*6 | 300*150 | 323.8 | 168.3 | 203 |

| 4*2 1/2 | 100*65 | 114.3 | 73 | 102 | 12*5 | 300*125 | 323.8 | 141.3 | 203 | |||||

| 1 1/2*1 1/4 | 40*32 | 48.3 | 42.2 | 64 | 4*2 | 100*50 | 114.3 | 60.3 | 102 | |||||

| 1 1/2*1 | 40*25 | 48.3 | 33.4 | 64 | 4*1 1/2 | 100*40 | 114.3 | 48.3 | 102 | 14*12 | 350*300 | 355.6 | 323.8 | 330 |

| 1 1/2*3/4 | 40*20 | 48.3 | 26.7 | 64 | 14*10 | 350*250 | 355.6 | 273 | 330 | |||||

| 1 1/2*1/2 | 40*15 | 48.3 | 21.3 | 64 | 5*4 | 125*100 | 141.3 | 114.3 | 127 | 14*8 | 350*200 | 355.6 | 219.1 | 330 |

| 5*3 1/2 | 125*90 | 141.3 | 101.6 | 127 | 14*6 | 350*150 | 355.6 | 168.3 | 330 | |||||

| 2*1 1/2 | 50*40 | 60.3 | 48.3 | 76 | 5*3 | 125*80 | 141.3 | 88.9 | 127 | |||||

| 2*1 1/4 | 50*32 | 60.3 | 42.2 | 76 | 5*2 1/2 | 125*65 | 141.3 | 73 | 127 | 16*14 | 400*350 | 406.4 | 355.6 | 356 |

| 2*1 | 50*25 | 60.3 | 33.4 | 76 | 5*2 | 125*50 | 141.3 | 60.3 | 127 | 16*12 | 400*300 | 406.4 | 323.8 | 356 |

| 2*3/4 | 50*20 | 60.3 | 26.7 | 76 | 16*10 | 400*250 | 406.4 | 273 | 356 | |||||

| 6*5 | 150*125 | 168.3 | 141.3 | 140 | 16*8 | 400*200 | 406.4 | 219.1 | 356 | |||||

| 2 1/2*2 | 65*50 | 73 | 60.3 | 89 | 6*4 | 150*100 | 168.3 | 114.3 | 140 | |||||

| 2 1/2*1 1/2 | 65*40 | 73 | 48.3 | 89 | 6*3 1/2 | 150*90 | 168.3 | 101.6 | 140 | 18*16 | 450*400 | 457 | 406.6 | 381 |

| 2 1/2*1 1/4 | 65*32 | 73 | 42.2 | 89 | 6*3 | 150*80 | 168.3 | 88.9 | 140 | 18*14 | 450*350 | 457 | 355.6 | 381 |

| 2 1/2*1 | 65*25 | 73 | 33.4 | 89 | 6*2 1/2 | 150*65 | 168.3 | 73 | 140 | 18*12 | 450*300 | 457 | 323.8 | 381 |

| 3*2 1/2 | 80*65 | 88.9 | 73 | 89 | 18*10 | 450*250 | 457 | 219.1 | 381 | |||||

| 3*2 | 80*50 | 88.9 | 60.3 | 89 | 8*6 | 200*150 | 219.3 | 168.3 | 152 | |||||

| 3*1 1/2 | 80*40 | 88.9 | 48.3 | 89 | 8*5 | 200*125 | 219.3 | 141.3 | 152 | |||||

| 3*1 1/4 | 80*32 | 88.9 | 42.2 | 89 | 8*4 | 200*100 | 219.3 | 114.3 | 152 | |||||

| 8*3 1/2 | 200*90 | 219.3 | 101.6 | 152 |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668°C |

| Tensile Strength | 345-1000 MPa |

| Yield Strength | 275-830 MPa |

| Elongation | 10-25% |

Our products comply with industry standards including:

- ASTM B338

- ASME SB-338

- AMS 4941

- ISO 5832-2

Features of Titanium Concentric Products

- Exceptional corrosion resistance

- High strength-to-weight ratio

- Excellent biocompatibility

- Superior fatigue resistance

- Low thermal expansion

- Non-magnetic properties

Applications

Titanium Concentric products find critical applications in:

- Aerospace components

- Medical implants and devices

- Chemical processing equipment

- Oil and gas extraction systems

- Marine engineering

- High-performance automotive parts

Production and Processing Technology

We employ state-of-the-art manufacturing techniques to ensure the highest quality products:

- Precision CNC machining

- Advanced welding technologies

- Cold drawing and pilgering

- Specialized heat treatment processes

Production Process of Titanium Concentric Products

- Raw material selection and testing

- Initial forming (extrusion or forging)

- Precision machining to achieve concentricity

- Heat treatment for optimal mechanical properties

- Surface finishing (polishing, anodizing, etc.)

- Rigorous quality control and inspection

Quality Inspection

Every product undergoes:

- Dimensional accuracy checks

- Non-destructive testing (NDT)

- Chemical composition analysis

- Mechanical property verification

- Surface quality assessment

Factory

Why Choose TSM Technology?

TSM Technology stands out as your ideal partner for products. Our advanced material technology ensures high-purity titanium alloys, while our precision manufacturing capabilities deliver ultra-tight tolerances and customized surface treatments. We boast comprehensive certifications including ISO 9001/13485, AS9100D, and NADCAP, guaranteeing compliance across industries. Our traceability management and sustainable production practices underscore our commitment to quality and environmental responsibility. We offer industry-specific solutions, rapid response to special requirements, and global supply chain assurance. With strategic raw material reserves and smart logistics, we ensure uninterrupted supply for your critical projects.

Package and Shipping

FAQ

- Q: What makes products superior to other materials?

A: The products offer an unmatched combination of strength, lightweight, and corrosion resistance, ideal for demanding applications. - Q: Can you provide custom product solutions?

A: Yes, we specialize in tailoring our products to meet specific customer requirements and industry standards. - Q: What industries commonly use products?

A: Aerospace, medical, chemical processing, and marine industries are major users of our products. - Q: How do you ensure the quality of your products?

A: We employ rigorous quality control measures, including advanced testing equipment and comprehensive inspection processes. - Q: What is the typical lead time for orders?

A: Lead times vary based on specifications and quantity. Please contact us for a precise estimate for your project.

Contact Us

Ready to elevate your project with premium Titanium Concentric? Contact TSM Technology today:

Email: info@tsm-technology.com