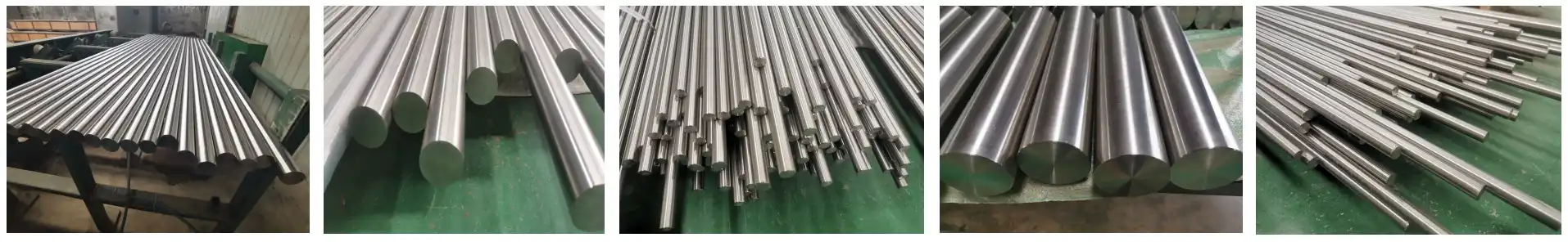

Nickel Round Bar

Supply Ability: 300 Tons/month

Grade: Inconel 600/625,Hastelloy C276,Incoloy 800/800H

Standard: ASTM B164 / B166 / ASME SB164

Diameter: 3mm - 500mm

Condition: Hot forged/cold drawn, solution annealed

Material Certification: MTC and SGS test reports available

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Round Bar Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of high-quality Nickel Round Bar. With over 14 years of experience, we've established ourselves as a trusted partner in the precision engineering industry. Our product offers superior corrosion resistance, excellent mechanical properties, and exceptional performance in extreme environments. We pride ourselves on delivering premium alloy solutions that meet the exacting standards of industries such as aerospace, chemical processing, and marine engineering.

What are Nickel Round Bars?

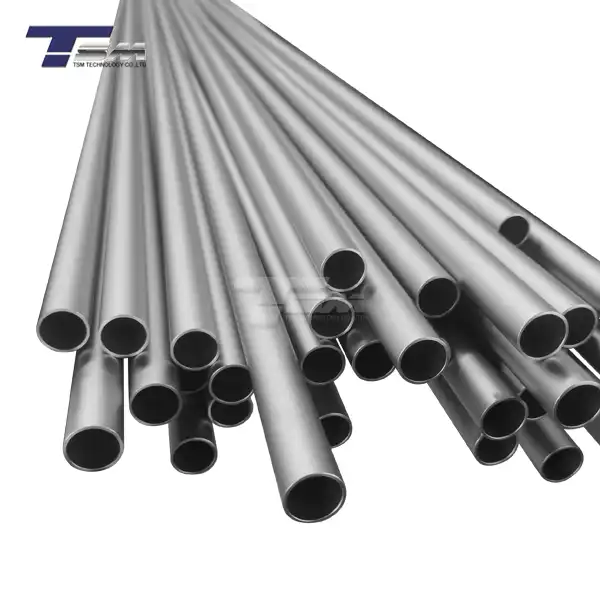

The products are cylindrical metal rods composed primarily of nickel. These versatile components are essential in various industrial applications due to their unique combination of strength, durability, and resistance to corrosion and high temperatures.

Specification

| Property | Value |

|---|---|

| Diameter Range | 3mm - 300mm |

| Length | Up to 6 meters (custom lengths available) |

| Tolerances | As per ASTM B160 |

| Surface Finish | Smooth, polished, or as per customer requirements |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.9 g/cm³ |

| Melting Point | 1455°C (2651°F) |

| Electrical Resistivity | 6.84 x 10-8 Ω-m |

| Thermal Conductivity | 90.9 W/m-K |

| Composition | Ni 99.0% min, C 0.15% max, Mn 0.35% max, Si 0.35% max |

Product Standards

Our products comply with international standards including:

- ASTM B160

- ASME SB160

- DIN 17740

- EN 10204 3.1

Features of Nickel Round Bar

- Excellent corrosion resistance in various environments

- High strength and ductility

- Superior performance at elevated temperatures

- Good weldability and machinability

- Non-magnetic properties

- Resistance to oxidation and scaling

Production Process of Nickel Round Bar

At TSM Technology, we employ advanced manufacturing techniques to ensure the highest quality nickel round bar production. Our process begins with rigorous raw material selection and testing, followed by precise melting and casting using vacuum induction melting and electro slag remelting technologies. The material then undergoes hot working (forging or rolling) as well as hot extrusion to achieve the desired form. Subsequent cold drawing or turning refines the dimensions, while specialized heat treatment optimizes the material properties. The production process concludes with precision machining and finishing, followed by comprehensive quality inspection and testing to guarantee superior performance and reliability. This integrated approach combines cutting-edge processing technologies with strict quality control at every stage.

Quality Inspection

We maintain rigorous quality control measures:

- Chemical composition analysis

- Mechanical property testing

- Non-destructive testing (ultrasonic, eddy current)

- Dimensional and surface inspections

- Microstructure examination

Applications

Nickel Round Bars find extensive use in:

- Chemical processing equipment

- Heat exchangers and condensers

- Aerospace components

- Marine engineering

- Oil and gas industry

- Electronic and electrical devices

- Nuclear power plants

Factory

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for the product due to our advanced material technology and purity control, ensuring high-grade alloys. Our precision manufacturing capabilities deliver ultra-tight tolerances and customized surface treatments, meeting the inert requirements of biomedical equipment and corrosion resistance needs of chemical processing. We maintain a comprehensive quality assurance system with certifications including ISO 9001/13485, AS9100D, and NADCAP, guaranteeing compliance across industries. Our sustainable production methods, industry-specific solutions, and global supply chain ensure we meet diverse needs efficiently. With strategic raw material reserves and smart logistics, we offer unparalleled responsiveness and reliability in the product supply.

Package and Shipping

TSM Technology ensures secure, custom packaging for damage-free transit. We offer global shipping with flexible Incoterms (EXW, FOB, CIF, etc.) and optimized logistics for fast, reliable delivery. Tracking is provided for all shipments.

FAQ

Q: What is the minimum order quantity for products?

A: Our MOQ is typically 100 kg, but we can accommodate smaller orders for specialty sizes.

Q: Can you provide custom diameters or lengths?

A: Yes, we offer customization services to meet your specific requirements.

Q: What is the lead time for product orders?

A: Standard lead times range from 2-4 weeks, depending on specifications and quantity.

Q: Do you provide material certifications with each order?

A: Yes, we provide full material test reports (MTRs) with every shipment.

Q: How do you ensure the quality of your products?

A: We employ strict quality control measures throughout production and conduct thorough inspections before shipping.

Contact Us

For inquiries or to place an order about Nickel Round Bar, please contact us:

Email: info@tsm-technology.com

_1752550122066.webp)