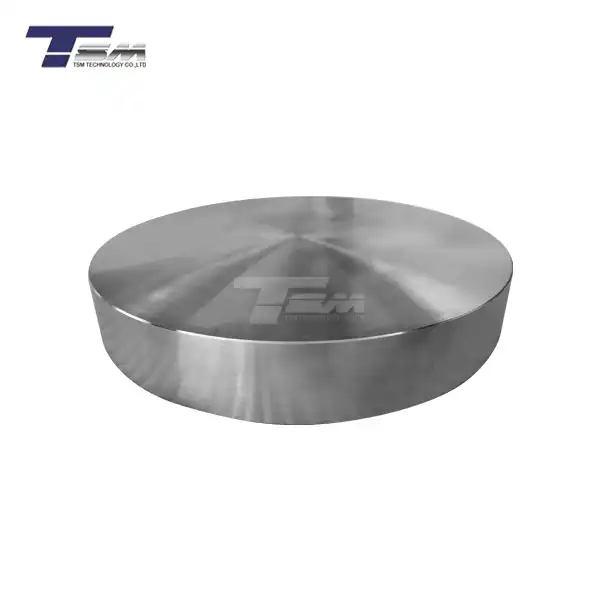

Nickel Alloy Forged Ring

Supply Ability: 300 Tons/month

Grade: Nickel 200, MONEL 400, INCONEL 600, INCONEL 718

Standard: ASTM B564

OD Range: 200mm - 5000mm

ID Range: 100mm - 4500mm

Height: 50mm - 1000mm

Process: Radial-axial forged

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy Forged Rings Manufacturer and Supplier

Welcome to TSM Technology Co., Ltd., your trusted manufacturer and supplier of high-quality Nickel Alloy Forged Rings. With over 14 years of experience, we've built a reputation for excellence in the precision engineering industry. Our products are designed to meet the most demanding requirements across various sectors, including oil and gas, aerospace, and chemical processing. Discover why industry leaders choose TSM for their critical component needs.

What are Nickel Alloy Forged Rings?

The Nickel Alloy Forged Rings are precision-engineered components manufactured through a forging process using nickel-based alloys. These rings offer exceptional strength, corrosion resistance, and high-temperature performance, making them ideal for extreme environments.

Specifications

| Property | Range |

|---|---|

| Outer Diameter | 100mm - 3000mm |

| Inner Diameter | 50mm - 2500mm |

| Height | 20mm - 1000mm |

| Weight | Up to 5000kg |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.4 - 8.9 g/cm³ |

| Melting Point | 1300°C - 1450°C |

| Tensile Strength | 600 - 1200 MPa |

| Yield Strength | 250 - 800 MPa |

| Elongation | 20 - 50% |

Product Standards

Our products comply with international standards including ASTM, ASME, API, and EN specifications.

Features of Nickel Alloy Forged Rings

- Exceptional corrosion resistance

- High-temperature strength

- Excellent fatigue resistance

- Superior weldability

- Remarkable stress-corrosion cracking resistance

Production Process of Nickel Alloy Forged Rings

At TSM Technology, we produce premium nickel alloy forged rings through a precision-controlled manufacturing process. Our production begins with strict raw material selection and testing, followed by precise cutting and controlled heating of nickel alloy billets. Using advanced open-die forging and ring rolling techniques, we achieve optimal grain flow and material density.

Each ring undergoes specialized heat treatment to enhance its mechanical properties and microstructure, followed by precision machining to meet exact dimensional specifications. Our comprehensive quality assurance includes:

- Ultrasonic testing for internal integrity

- Magnetic particle and dye penetrant inspection for surface defects

- Precise dimensional verification

- Full material composition analysis

This rigorous manufacturing and inspection process ensures our nickel alloy forged rings meet the most demanding specifications for aerospace, power generation, and oil & gas applications.

Applications

Nickel Alloy Forged Rings are crucial components in:

- Oil and gas valves and wellheads

- Aerospace engine parts

- Chemical processing reactors

- Power generation turbines

- Marine propulsion systems

Factory

Why Choose TSM Technology?

At TSM Technology, we pride ourselves on our cutting-edge material technology and purity control, ensuring high-purity alloys for your critical applications. Our precision manufacturing capabilities deliver ultra-tight tolerances and custom surface treatments like sandblasting, pickling, and polishing to meet specific industry needs.

We maintain a comprehensive quality assurance system, holding certifications including ISO 9001/13485 (Medical), AS9100D (Aerospace), and NADCAP (Heat Treatment). Our traceability management ensures full product history documentation. We're committed to sustainable production, implementing green manufacturing processes and material recycling.

TSM offers tailored solutions for medical, energy, chemical, and aerospace sectors, with rapid response to special requirements. Our global supply chain and strategic raw material reserves guarantee reliable deliveries, supported by smart warehousing and logistics.

Package and Shipping

We ensure secure packaging and reliable shipping to protect your products during transit.

FAQ

Q: What alloys do you use for your products?

A: We offer a range including Inconel, Hastelloy, and Monel alloys.

Q: Can you provide custom sizes for products?

A: Yes, we specialize in custom-sized rings to meet your specific requirements.

Q: What is the typical lead time for products?

A: Lead times vary based on specifications, typically ranging from 4-12 weeks.

Q: Do you offer material certifications with your products?

A: Absolutely. We provide full material certifications and test reports.

Q: Can TSM Technology assist with material selection for my application?

A: Yes, our expert team offers comprehensive material selection support.

Contact Us

Ready to elevate your project with our superior Nickel Alloy Forged Rings? Contact TSM Technology today:

Email: info@tsm-technology.com Let's forge a stronger future together with TSM Technology's products.