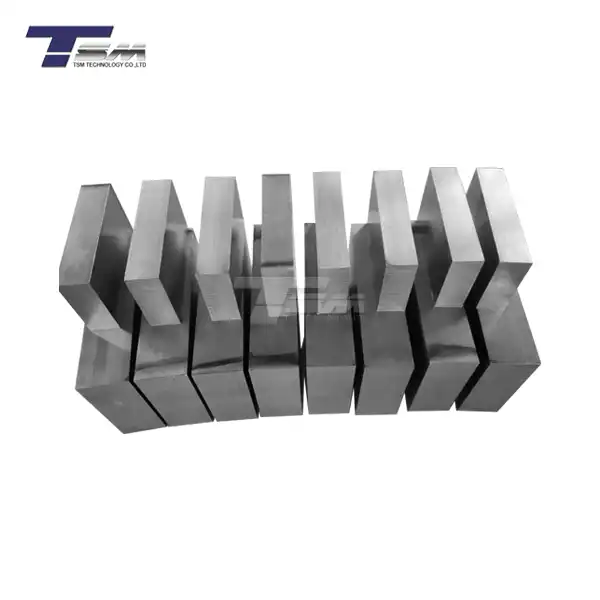

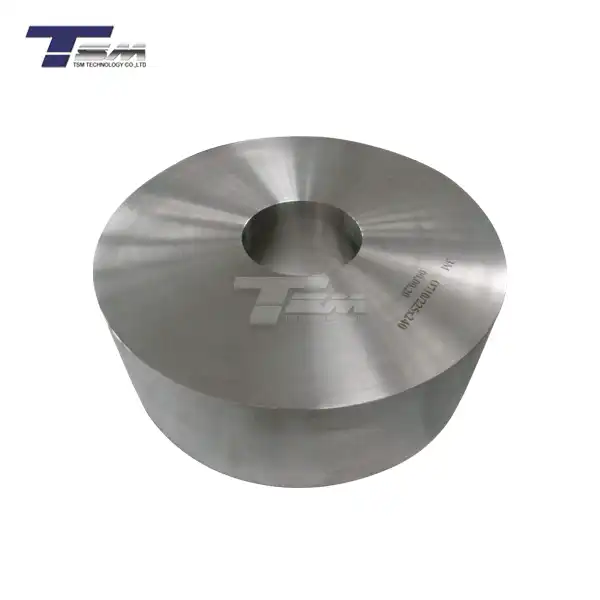

Titanium Forged Block

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: F1、F2、F4、F5、F7、F9、F12

Standard: ASTM B381

Dimensions: 100×100×100mm - 2000×2000×1000mm

Stress-relieved with 3D ultrasonic mapping available.

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Forged Blocks Manufacturer and Supplier

At TSM Technology Co., Ltd., we're your trusted manufacturer and supplier of premium Titanium Forged Blocks. With over 14 years of experience in superior alloy production, we've established ourselves as industry leaders. Our products offer unparalleled strength, corrosion resistance, and precision for aerospace, medical, and industrial applications. Discover why global innovators choose TSM for their critical titanium components.

What are Titanium Forged Blocks?

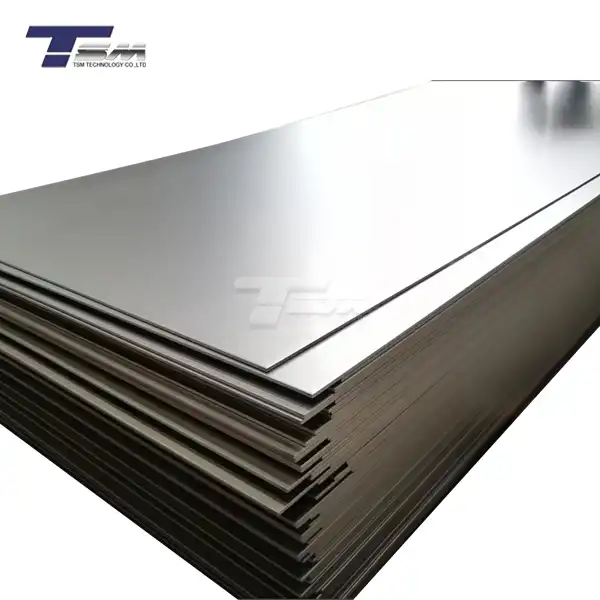

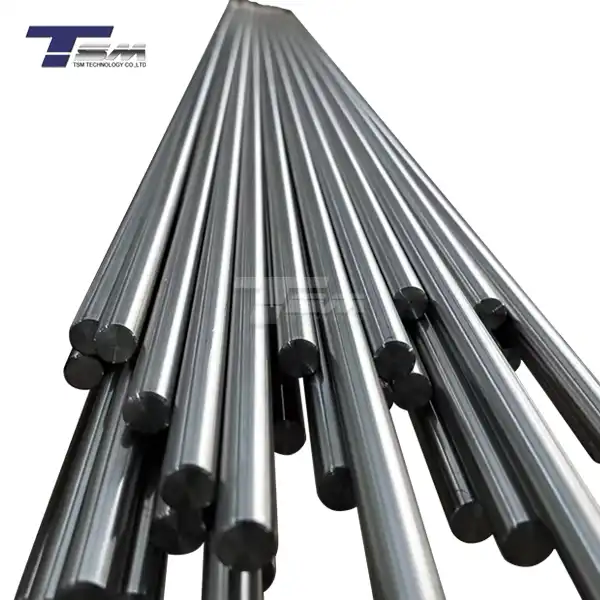

The Titanium Forged Blocks are high-strength, lightweight components produced through advanced forging processes. These blocks serve as the foundation for precision-engineered parts in demanding industries. Our titanium blocks offer exceptional mechanical properties, superior corrosion resistance, and biocompatibility.

Specifications

| Property | Value |

|---|---|

| Grades Available | Grade 2, Grade 5 (Ti-6Al-4V), Grade 23 (ELI) |

| Dimensions | Custom sizes up to 2000mm x 2000mm x 1000mm |

| Surface Finish | As-forged, Machined, or Custom |

| Heat Treatment | Solution-treated and aged (STA) available |

Physical and Chemical Properties

| Property | Grade 2 | Grade 5 (Ti-6Al-4V) | Grade 23 (ELI) |

|---|---|---|---|

| Tensile Strength (MPa) | 345 | 895 | 860 |

| Yield Strength (MPa) | 275 | 828 | 795 |

| Elongation (%) | 20 | 10 | 10 |

| Density (g/cm³) | 4.51 | 4.43 | 4.43 |

Product Standards

Our products meet or exceed industry standards, including:

- ASTM B381

- AMS 4928

- ISO 5832-3 (for medical applications)

Features of Titanium Forged Blocks

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- High temperature performance

- Biocompatibility for medical applications

- Excellent fatigue resistance

- Low thermal expansion

Production Process of Titanium Forged Blocks

TSM Technology utilizes cutting-edge forging technology to produce premium titanium forged blocks through a meticulously controlled process. We begin with rigorous raw material selection and testing of titanium billets, followed by precision preheating to optimal forging temperatures. Our state-of-the-art closed-die forging process, combined with vacuum arc remelting (VAR) technology, ensures superior material purity and structural integrity.

Each block undergoes specialized heat treatment to enhance mechanical properties, followed by comprehensive quality inspection including non-destructive testing. For customer-specific applications, our advanced CNC machining capabilities deliver precise final dimensions, with optional surface treatments available. The process concludes with protective packaging to maintain product quality during transit.

This integrated approach, combining advanced forging techniques with precision finishing, results in titanium blocks that meet the most demanding aerospace, defense, and industrial requirements for strength, durability, and performance reliability.

Quality Inspection

Every product undergoes rigorous quality control:

- Ultrasonic testing for internal defects

- Chemical composition analysis

- Mechanical property testing

- Dimensional accuracy verification

- Microstructure examination

Applications

- Aerospace: Structural components, landing gear parts

- Medical: Implants, surgical instruments

- Oil & Gas: Valves, pumps, offshore equipment

- Automotive: High-performance engine components

- Industrial: Chemical processing equipment, heat exchangers

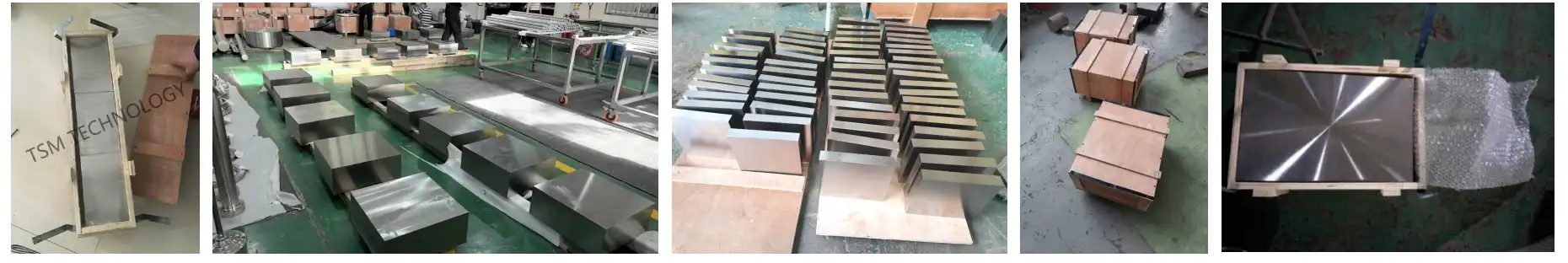

Factory

Why Choose TSM Technology?

TSM Technology stands out as your premier partner for products. Our cutting-edge material technology ensures high-purity titanium, while our precision manufacturing delivers ultra-tight tolerances. We offer customized surface treatments like sandblasting and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees full compliance and traceability. We excel in sustainable production, utilizing green manufacturing processes and efficient material recycling. Our global supply chain and strategic raw material reserves ensure reliable delivery, even for urgent requests. Choose TSM for tailored solutions in the medical, energy, and aerospace sectors, backed by rapid response capabilities and deep application expertise.

Package and Shipping

At TSM Technology, we ensure your titanium forged rings arrive safely with custom protective packaging designed to withstand transit stresses. Our global logistics network provides flexible door-to-door delivery solutions worldwide, supported by comprehensive export documentation and expert customs clearance assistance for seamless international shipments.

FAQ

Q: What is the minimum order quantity for products?

A: We accommodate various order sizes, from single prototype blocks to large production runs. Contact us for specific MOQ details.

Q: Can you provide material certifications with each order?

A: Yes, we provide comprehensive material test reports (MTRs) and certifications with every shipment.

Q: What is the lead time for custom products?

A: Lead times vary based on specifications and quantity. Typically, we can deliver within 4-8 weeks for standard orders.

Q: Do you offer machining services for the forged blocks?

A: Yes, we provide full CNC machining capabilities to deliver finished components to your exact specifications.

Q: Are your products suitable for medical implants?

A: Absolutely. Our Grade 23 (ELI) titanium blocks meet all necessary standards for medical implant manufacturing.

Contact Us

Ready to elevate your projects with premium Titanium Forged Blocks? Contact TSM Technology today:

Email: info@tsm-technology.com