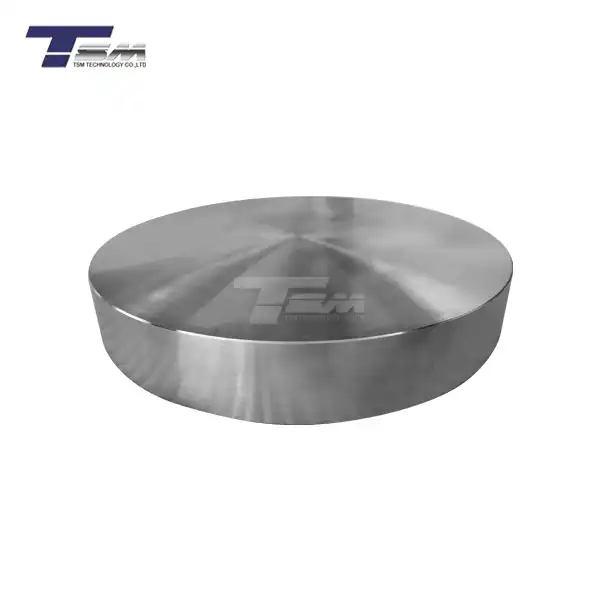

Nickel Alloy Forged Disc

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: Nickel 201/200,Monel K500/400,Inconel 718/600

Standard: ASTM B564 / ASME SB564

Diameter: 100mm - 3000mm

Thickness: 20mm - 500mm

Testing: 100% ultrasonic examination(UT)

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy Forged Discs Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of Nickel Alloy Forged Discs. With over 14 years of experience, we deliver superior quality and precision-engineered products to meet the demanding requirements of industries worldwide. Our products are renowned for their exceptional strength, corrosion resistance, and durability in extreme environments.

What are Nickel Alloy Forged Discs?

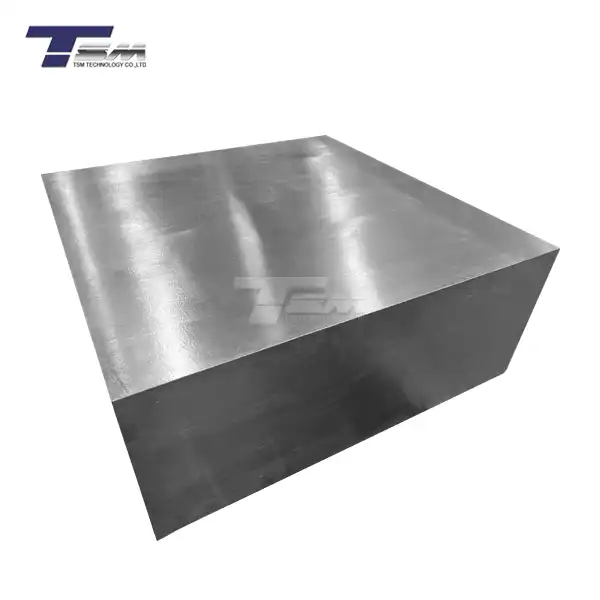

The Nickel Alloy Forged Discs are high-performance components crafted from advanced nickel-based alloys. These discs offer superior mechanical properties and outstanding resistance to corrosion, heat, and wear. They are essential in critical applications across various industries.

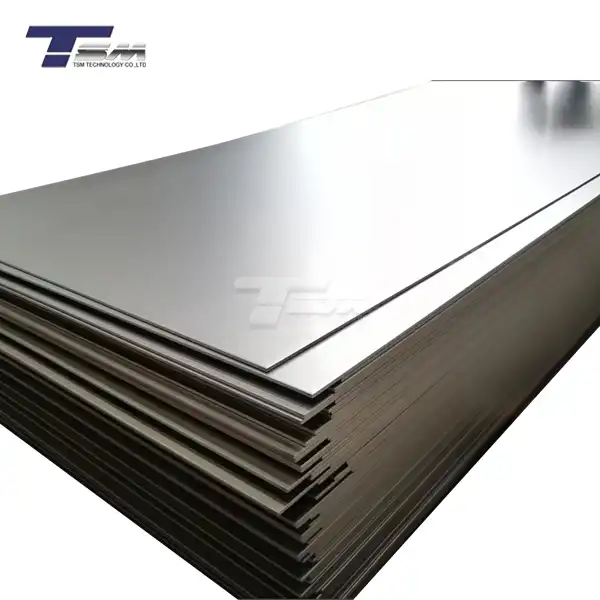

Specifications

| Property | Value |

|---|---|

| Diameter | 50mm - 2000mm |

| Thickness | 10mm - 500mm |

| Weight | Up to 5000 kg |

| Alloy Grades | Inconel, Monel, Hastelloy, Incoloy |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.0 - 9.0 g/cm³ |

| Melting Point | 1300°C - 1450°C |

| Tensile Strength | 550 - 1200 MPa |

| Yield Strength | 200 - 850 MPa |

| Elongation | 20 - 50% |

Product Standards

Our products comply with international standards, including:

- ASTM B564

- ASME SB564

- AMS 5665

- NACE MR0175

Features of Nickel Alloy Forged Discs

- Exceptional corrosion resistance

- High-temperature strength

- Excellent fatigue resistance

- Superior weldability

- Remarkable dimensional stability

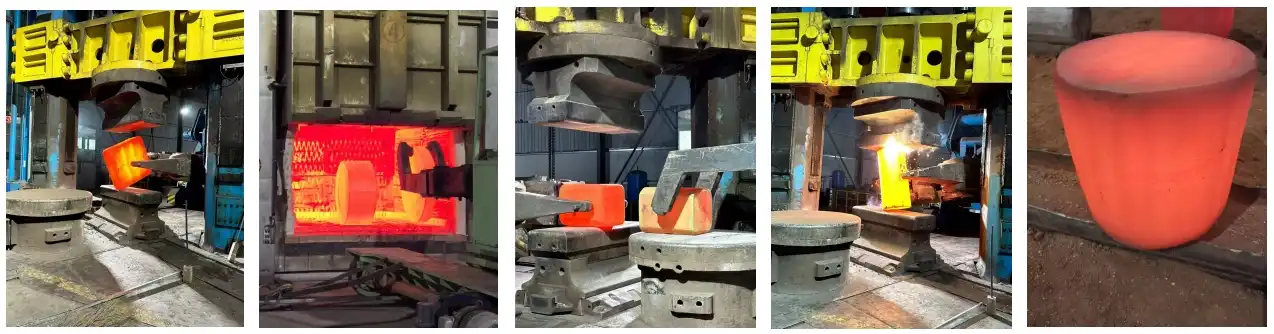

Production and Processing of Nickel Alloy Forged Discs

At TSM Technology, we produce high-performance titanium components through an advanced manufacturing process that begins with meticulous raw material selection and testing. Our production involves precision heating and forging to achieve optimal grain structure, followed by controlled heat treatment including solution annealing and aging to enhance mechanical properties. Components then undergo precision machining and surface finishing to meet exact specifications.

Quality is assured through comprehensive testing:

Chemical composition verification

Mechanical property validation

Non-destructive testing (ultrasonic and dye penetrant)

Precise dimensional inspection

This rigorous process ensures our titanium products meet the highest industry standards for critical aerospace, medical, and industrial applications.

Applications

Nickel Alloy Forged Discs are crucial in:

- Oil and gas exploration

- Aerospace components

- Chemical processing equipment

- Power generation turbines

- Marine engineering

- Nuclear reactors

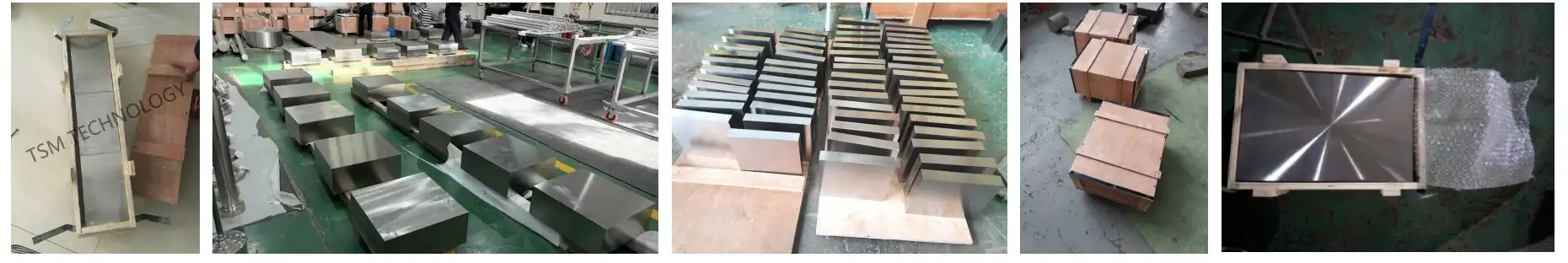

Factory

Why Choose TSM Technology?

At TSM Technology, we pride ourselves on delivering excellence:

- Cutting-edge material technology and purity control ensure high-grade alloys.

- Precision manufacturing with ultra-tight tolerances and customized surface treatments.

- Comprehensive quality assurance with ISO 9001/13485, AS9100D, and NADCAP certifications.

- Full traceability management for every product.

- Sustainable production practices with efficient resource utilization.

- Industry-specific solutions for medical, energy, and aerospace sectors.

- Rapid response to special requirements with application-specific expertise.

- Global supply chain reliability and strategic raw material reserves.

- Smart warehousing and logistics for efficient order fulfillment.

- Continuous innovation in alloy development and processing techniques.

Package and Shipping

FAQ

Q: What is the minimum order quantity for products?

A: We offer flexible MOQs based on alloy grade and dimensions. Contact us for details.

Q: Can you provide custom sizes and alloy compositions?

A: Yes, we specialize in customized solutions to meet your specific requirements.

Q: What is the typical lead time for products?

A: Lead times vary from 2-8 weeks depending on specifications and quantity.

Q: Do you offer material certifications with each order?

A: Absolutely. We provide comprehensive material test reports (MTRs) with every shipment.

Q: How do you ensure the quality of your products?

A: We maintain strict quality control throughout production, including advanced NDT methods and third-party inspections.

Contact Us

Ready to elevate your projects with our superior Nickel Alloy Forged Discs? Contact our expert team today for personalized assistance and quotations.

Email: info@tsm-technology.com