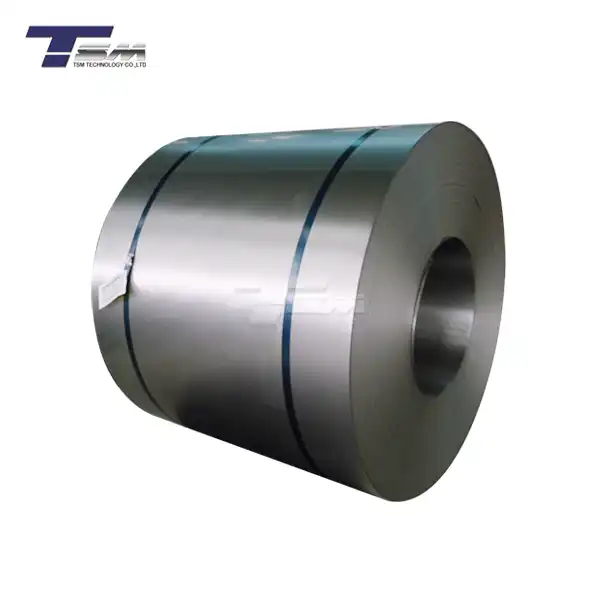

Nickel Coil

Supply Ability: 300 Tons/month

Grade: Inconel 718/600/625/X-750,Hastelloy C276/C22

Standard: ASTM B162 / B164

Thickness: 0.1mm - 6.0mm

Width: 50mm - 600mm

Coil Weight: Up to 5,000kg (custom slitting available)

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

Nickel Coil Manufacturer and Supplier

Your trusted manufacturer and supplier of premium Nickel Coil products. With over 14 years of experience, we specialize in delivering high-quality nickel alloys to meet the demanding needs of various industries. Our product offerings combine superior purity, precise manufacturing, and reliable performance to support your critical applications in pharmaceuticals, marine engineering, oil and gas, and medical sectors.

What are Nickel Coils?

The Nickel Coil is a versatile material known for its excellent corrosion resistance, high temperature stability, and impressive mechanical properties. These coils are essential components in numerous industrial applications, offering durability and reliability in challenging environments.

Specification

| Property | Value |

|---|---|

| Purity | 99.9% minimum |

| Thickness | 0.1mm - 10mm |

| Width | 10mm - 1000mm |

| Temper | Annealed, Half-Hard, Full-Hard |

| Surface Finish | Bright, Matte |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Melting Point | 1455°C (2651°F) |

| Density | 8.9 g/cm³ |

| Electrical Resistivity | 6.84 µΩ-cm |

| Thermal Conductivity | 90.9 W/m-K |

| Yield Strength | 59-480 MPa |

Product Standards

Our products comply with international standards, including:

- ASTM B162

- ASTM B168

- AMS 5540

- AMS 5557

Features of Nickel Coil

- Exceptional corrosion resistance

- High temperature stability

- Excellent mechanical strength

- Superior electrical and thermal conductivity

- Magnetic properties

- Formability and weldability

Applications

Nickel Coil finds extensive use in:

- Battery manufacturing for electric vehicles

- Aerospace components

- Chemical processing equipment

- Heat exchangers

- Electronics and semiconductor production

- Marine engineering

- Medical devices

Production and Processing Technology

At TSM Technology, we employ advanced manufacturing techniques to ensure the highest quality product:

Precision rolling for tight tolerance control

01

Controlled atmosphere annealing for optimal grain structure

02

Surface treatment options include pickling, polishing, and passivation

03

Cutting-edge slitting and coiling equipment for precise dimensions

04

Production Process and Quality Inspection Of Nickel Coil

TSM Technology's nickel coil production begins with certified raw materials undergoing strict composition testing. Through precision hot/cold rolling and controlled annealing, we achieve exact gauges (0.1-10mm) with uniform mechanical properties. Our 7-stage quality control includes XRF composition verification (to ASTM/EN standards), tensile testing (yield strength 200-1000MPa), laser micrometer dimensional checks (±0.01mm tolerance), and eddy current testing for micro-defect detection. Each coil receives mirror/brush finishing (Ra 0.1-1.6μm) before protective VCI packaging, ensuring aerospace-grade (AMS 5599) and industrial (ASTM B162) compliance for chemical processing, battery, and marine applications.

Nickel Coil-Factory Stock

Why Choose TSM Technology?

TSM Technology stands out as your premier product partner due to our cutting-edge material technology and purity control. We offer precision manufacturing with ultra-tight tolerances and customized surface treatments, catering to diverse industry needs. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, ensures product excellence and traceability. We excel in sustainable production, industry-specific solutions, and rapid response to special requirements. With a robust global supply chain and strategic raw material reserves, we guarantee reliable delivery and consistent quality. Choose TSM for unparalleled expertise in medical, energy, chemical, and aerospace applications.

Package and Shipping

TSM Technology ensures secure shipment with protective coil wrapping and palletization, while offering customized packaging solutions. Our global logistics network provides both standard and express delivery options, guaranteeing timely worldwide distribution for urgent and routine orders alike.

FAQ

- Q: What is the minimum order quantity for the product?

A: Our minimum order quantity is 100kg, but we can accommodate smaller orders for special requirements. - Q: Can you provide custom dimensions for the product?

A: Yes, we offer custom slitting and coiling services to meet your specific dimensional needs. - Q: What is the lead time for product orders?

A: Standard lead time is 2-3 weeks, but we can expedite orders for urgent needs. - Q: Do you provide material certificates with each order?

A: Yes, we provide full material test reports (MTR) and certifications with every shipment. - Q: Can TSM Technology assist with material selection for specific applications?

A: Absolutely. Our technical team can provide expert guidance on material selection based on your application requirements.

Contact Us

Ready to elevate your projects with our premium Nickel Coil? Contact TSM Technology today for expert assistance and quotations.

Email: info@tsm-technology.com

_1752550122066.webp)