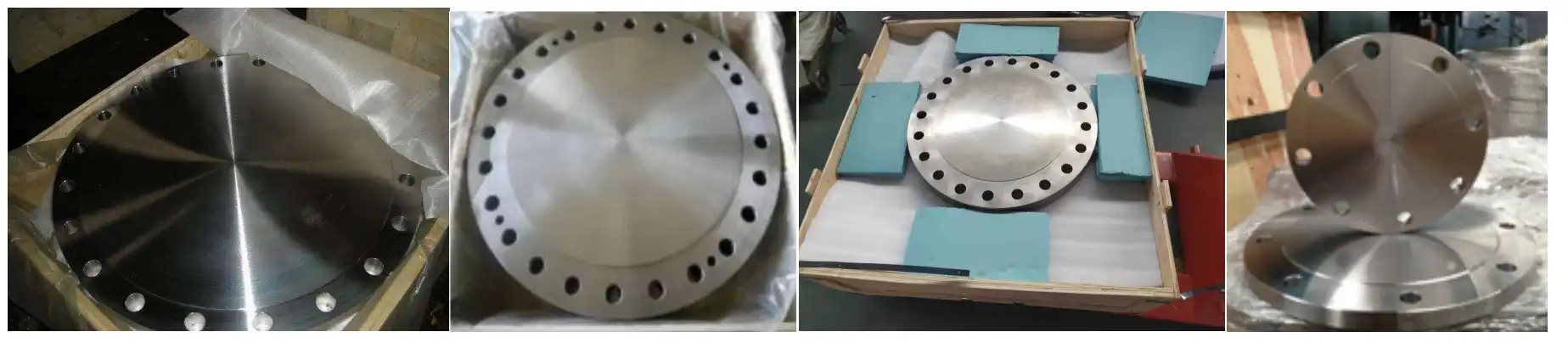

Nickel Alloy BL Flange

3 factories*8 production lines*70+ machines

Grade: MONEL 400, INCONEL 600, HASTELLOY C276

Standard: ASME B16.5

Finish: Machine faced with drilled bolt holes

Marking: Laser etched with material grade

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy BL Flanges Manufacturer and Supplier

At TSM Technology Co., Ltd., we're your trusted manufacturer and supplier of high-quality Nickel Alloy BL Flanges. With over 14 years of experience, we've built a reputation for innovation and reliability in superior nickel alloys. Our products offer exceptional corrosion resistance and durability, making them ideal for harsh environments in oil & gas, chemical processing, and marine applications.

What are Nickel Alloy BL Flanges?

The products are basic components utilized in channeling frameworks where extraordinary erosion resistance and high-temperature execution are essential. These ribs are fabricated from premium nickel-based combinations, advertising prevalent quality and solidity compared to standard stainless steel choices.

Specifications

| Property | Value |

|---|---|

| Material | Nickel Alloy (e.g., Inconel, Monel, Hastelloy) |

| Types | Weld Neck, Slip-On, Blind, Socket Weld |

| Sizes | 1/2" to 24" NPS |

| Pressure Ratings | Class 150 to 2500 |

| Face Types | Raised Face, Flat Face, Ring Type Joint |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 80,000 - 120,000 psi |

| Yield Strength | 35,000 - 60,000 psi |

| Elongation | 30% - 50% |

| Hardness | 80 - 95 HRB |

| Melting Point | 2300°F - 2600°F (1260°C - 1427°C) |

Product Standards

Our products comply with international standards, including:

- ASTM B564

- ASME B16.5

- NACE MR0175 / ISO 15156

- PED 2014/68/EU

Features of Nickel Alloy BL Flanges

- Exceptional corrosion resistance in aggressive environments

- High-temperature strength and stability

- Excellent resistance to stress corrosion cracking

- Superior weldability and fabricability

- Long service life, reducing maintenance costs

Applications

Nickel Alloy BL Flanges are widely used in:

- Offshore oil and gas platforms

- Chemical processing plants

- Power generation facilities

- Marine and shipbuilding industries

- Aerospace and defense sectors

Production and Processing Technology

We utilize advanced CNC machining and heat treatment processes to ensure precise dimensional accuracy and optimal material properties. Our state-of-the-art facilities allow for custom surface treatments, including shot blasting, pickling, and polishing.

Production Process of Nickel Alloy BL Flanges

- Raw material selection and testing

- Forging or casting of flange blanks

- CNC machining to achieve final dimensions

- Heat treatment for optimal mechanical properties

- Surface finishing (if required)

- Quality inspection and testing

- Marking and packaging

Quality Inspection

Our rigorous quality control process includes:

- Material composition analysis

- Dimensional checks

- Non-destructive testing (NDT)

- Hydrostatic pressure testing

- Review of material certificates and test reports

Packaging and Shipping

We ensure secure packaging of our products to prevent damage during transit. Our global logistics network supports efficient customs clearance and timely delivery to your facility.

Why Choose TSM Technology?

At TSM Technology, we offer more than just high-quality products. Our commitment to excellence extends throughout our entire operation:

- Advanced material technology ensures high-purity alloys

- Precision manufacturing with ultra-tight tolerances

- Comprehensive quality assurance system with ISO 9001/13485, AS9100D, and NADCAP certifications

- Full traceability management

- Sustainable production practices with efficient resource utilization

- Customized solutions for specific industry needs

- Rapid response to special requirements

- Global supply chain reliability

- Strategic raw material reserves

Our expertise spans critical applications in medical, energy, chemical, and aerospace sectors, providing you with tailored solutions backed by years of industry experience.

Company Exhibition

FAQ

- Q: What is the lead time for products?

A: Standard sizes typically ship within 2-4 weeks. Custom orders may require 4-8 weeks. - Q: Can you provide material test reports (MTRs)?

A: Yes, we provide comprehensive MTRs with every order upon request. - Q: Do you offer custom dimensions or alloy grades?

A: Absolutely. We specialize in custom solutions to meet your specific requirements. - Q: What quality certifications do you hold?

A: We are ISO 9001, AS9100D, and NADCAP certified, ensuring the highest quality standards. - Q: Can you assist with material selection for specific applications?

A: Yes, our technical team offers expert guidance on alloy selection based on your operating conditions.

Contact Us

Ready to elevate your project with our superior Nickel Alloy BL Flanges? Contact our team of experts today for personalized assistance and quotes.

Email: info@tsm-technology.com

_1752550122066.webp)