Titanium Equal Tee

3 factories*8 production lines*70+ machines

Grade:WPT2,WPT7,WPT12

Standard: ASTM B363, ASME B16.9

Specification:SCH 5S to SCH 80S

DN15-DN1200

Butt-weld ends with PMI (Positive Material Identification) reports.

Material Certification: MTC and SGS test reports available

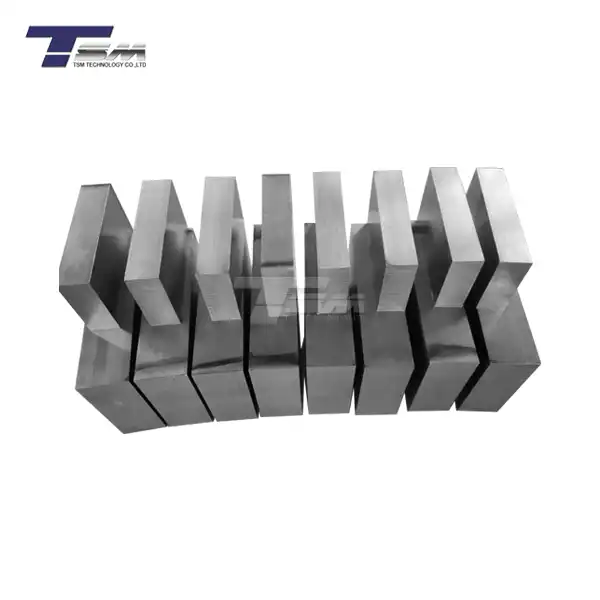

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Surface treatments: sandblasting/anodizing

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

Titanium Equal Tee Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of high-quality Titanium Equal Tee fittings. Our advanced manufacturing processes and stringent quality control ensure that our products meet the most demanding industry standards. With over 14 years of experience in superior alloy production, TSM Technology offers unparalleled expertise in crafting corrosion-resistant, high-strength piping components for critical applications across various sectors.

What are Titanium Equal Tees?

The product fittings are essential piping components used to create T-shaped junctions in fluid systems. These fittings are designed with three equal-sized outlets, allowing for the efficient distribution or combination of flow in multiple directions. Crafted from high-grade titanium alloys, these tees offer exceptional strength, corrosion resistance, and durability in challenging environments.

Specification

| Shape | Equal Tee (T/S), Reducing Tee (T/R) |

| Size | NPS1/2″-24″ (DN15-1200) Schedule 10s to Schedule 80 |

| Standard | ANSI B16.9, MSS SP 43, EN1092-1 |

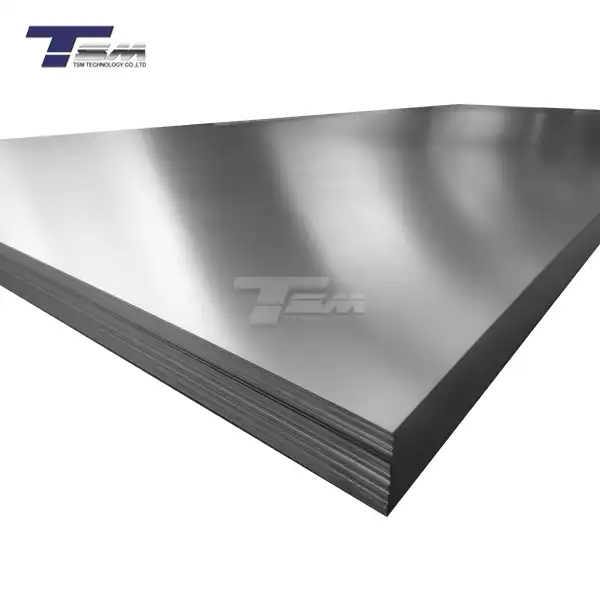

| Material | GR2 GR7 GR12, etc. |

| Wall thickness | SCH10S, SCH10, SCH40S,STD, SCH20,SCH30,SCH40, SCH60, SCH80, |

| End | bevel end, plain end |

| Surface | Sand blasting, Polishing, Pickling |

| Package | Wooden case, wooden pallets, or according to the customer’s requirements. |

| Certificate | ISO 9001 MTC EN10204.3.1 |

| Payment term | T/T, L/C, Western Union, etc. |

| Tee type | Equal tee, reducing tee, positive tee, inclined tee, threaded tee, clip tee, socket tee |

| Test | Third-party inspection: acceptable |

Dimension of Equal Tee

|

NPS |

O. D.(D) |

Center to End(C) |

Center to End(M) |

|

1/2 |

21.3 |

25 |

25 |

|

3/4 |

26.7 |

29 |

29 |

|

1 |

33.4 |

48 |

48 |

|

1-1/2 |

48.3 |

57 |

57 |

|

2 |

60.3 |

64 |

64 |

|

2-1/2 |

73 |

76 |

76 |

|

3 |

88.9 |

86 |

86 |

|

3-1/2 |

101.6 |

95 |

95 |

|

4 |

114.3 |

105 |

105 |

|

5 |

141.3 |

124 |

124 |

|

6 |

168.3 |

143 |

143 |

|

8 |

219.1 |

178 |

178 |

|

10 |

273 |

216 |

216 |

Physical and Chemical Properties

| Property | Grade 2 Titanium | Grade 5 Titanium |

|---|---|---|

| Tensile Strength | 345 MPa | 895 MPa |

| Yield Strength | 275 MPa | 828 MPa |

| Elongation | 20% | 10% |

| Density | 4.51 g/cm³ | 4.43 g/cm³ |

- ASTM B363

- ASME B16.11

- ASME B31.3

Features of Titanium Equal Tees

- Exceptional corrosion resistance

- High strength-to-weight ratio

- Excellent fatigue resistance

- Low thermal expansion

- Non-magnetic properties

- Biocompatibility

Applications

Titanium Equal Tee fittings find extensive use in:

- Offshore oil and gas pipelines

- Chemical processing plants

- Desalination facilities

- Aerospace fuel systems

- Marine environments

- Nuclear power plants

- Medical equipment manufacturing

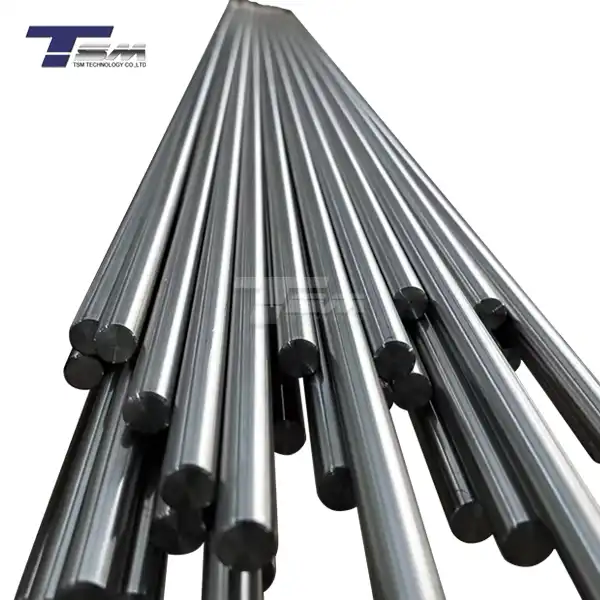

Production and Processing Technology

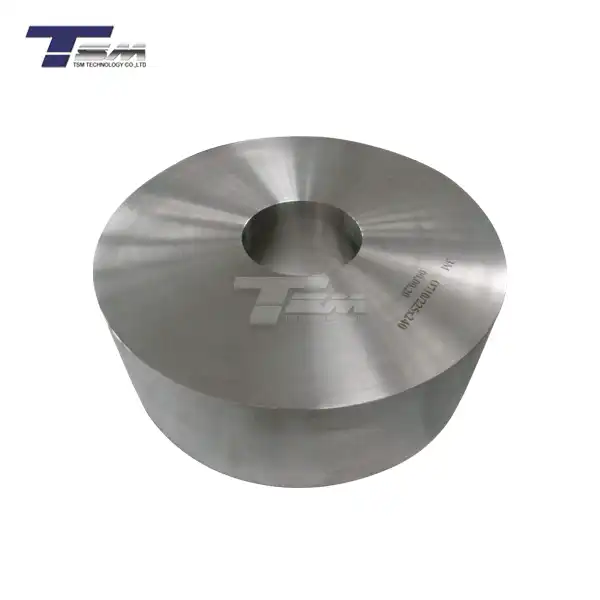

TSM Technology employs advanced CNC machining and precision forging techniques to manufacture our products. Our state-of-the-art facilities ensure tight dimensional tolerances and superior surface finishes.

Production Process of Titanium Equal Tees

- Raw material inspection

- CNC machining or forging

- Heat treatment

- Surface finishing

- Dimensional inspection

- Non-destructive testing

- Final quality control

Quality Inspection

Our rigorous quality assurance process includes:

- Material composition analysis

- Hydrostatic pressure testing

- Radiographic examination

- Ultrasonic testing

- Dye penetrant inspection

Package and Shipping

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for product solutions. Our cutting-edge material technology ensures high-purity titanium components with precision manufacturing capabilities that exceed standard tolerances. We offer customized surface treatments like sandblasting, pickling, and polishing to meet specific requirements for biomedical inertness or chemical corrosion resistance. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees full regulatory compliance and traceability. We excel in sustainable production practices and provide industry-tailored solutions for medical, energy, and aerospace sectors. With global supply chain resilience and strategic raw material reserves, we ensure fast response times and reliable delivery for all your specialized titanium fitting needs.

Factory and Stock

FAQ

Q: What is the typical lead time for products?

A: Standard sizes are usually available within 2-3 weeks. Custom orders may require 4-6 weeks.

Q: Can you provide material test reports (MTR) with each order?

A: Yes, we provide comprehensive MTRs detailing chemical composition and mechanical properties.

Q: Are your products suitable for cryogenic applications?

A: Yes, our Grade 2 titanium fittings perform excellently in cryogenic environments.

Q: Do you offer custom dimensions or special alloy grades?

A: Absolutely. We can manufacture custom sizes and use specialized titanium alloys upon request.

Q: What is the maximum pressure rating available for your products?

A: We offer fittings rated up to Class 3000, suitable for high-pressure applications.

Contact Us

For inquiries or to discuss your specific product requirements about Titanium Equal Tees, please contact our expert team:

Email: info@tsm-technology.com