Titanium Elbows

3 factories*8 production lines*70+ machines

Grade: WPT2,WPT7,WPT12

Standard: ASTM B363, ASME B16.9

Specification:1/2"-96" DN15-DN2400

Surface treatments: sandblasting/anodizing

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

Titanium Elbows Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of high-quality Titanium Elbows. Our advanced manufacturing processes and stringent quality control ensure that our products meet the most demanding industry standards. With over a decade of experience, TSM Technology has become a trusted partner for businesses requiring corrosion-resistant, high-performance piping components in extreme environments.

What are Titanium Elbows?

The Titanium Elbows are critical pipe fittings designed to change the direction of flow in piping systems. Made from pure titanium or titanium alloys, these elbows offer exceptional strength, corrosion resistance, and durability, making them ideal for use in harsh industrial environments.

Specification

|

Product Name |

Titanium Elbow (Seamless and welded) |

|

Material |

Titanium Gr1, Gr2, Gr5, Gr7, Gr12 |

|

Degree |

30D,45D,90D,120D,180D |

|

Wall thickness |

1.0mm/1.2mm |

|

Technical |

Pressing, welded, seamless |

|

Inspection of welding lines |

X-Ray Tests or Dye Penetrating Tests |

|

Material Test Report |

EN10204.3.1, Chemical Composition and Physical Properties |

|

Product Marking |

Available |

|

Application |

Exhaust pipe, motorcycle system, etc. |

|

Certificate |

Germany TUV Assessment, ISO9001:2008 |

|

package |

Plastic bag first, then form inside, plywood case outside |

Titanium 90°short Radius Elbows

Titanium 90°Long Radius Elbows

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ (Grade 2) |

| Melting Point | 1668°C (3034°F) |

| Tensile Strength | 345 MPa (Grade 2) |

| Yield Strength | 275 MPa (Grade 2) |

| Elongation | 20% (Grade 2) |

| Hardness | 160 HV (Grade 2) |

Product Standards

- ASTM B363

- ASME SB363

- ANSI B16.9

- MSS SP-43

Features of Titanium Elbows

- Exceptional corrosion resistance

- High strength-to-weight ratio

- Excellent fatigue resistance

- Low thermal expansion

- Non-magnetic properties

- Biocompatibility

Applications

- Oil and gas industry

- Chemical processing plants

- Desalination facilities

- Aerospace and defense

- Marine environments

- Nuclear power plants

- Medical equipment manufacturing

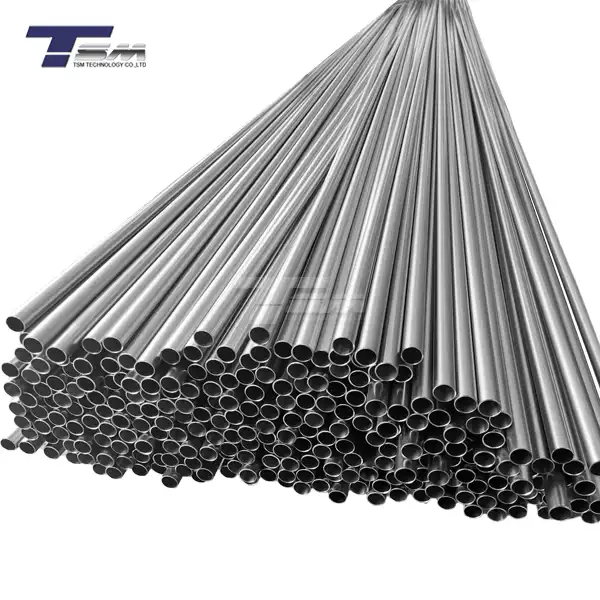

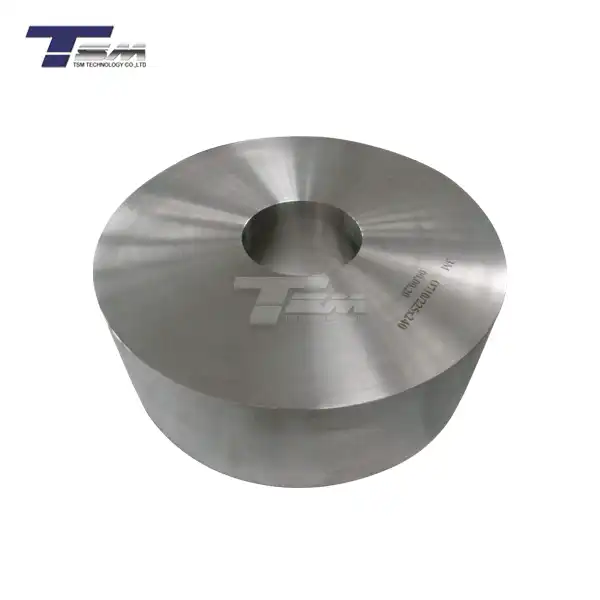

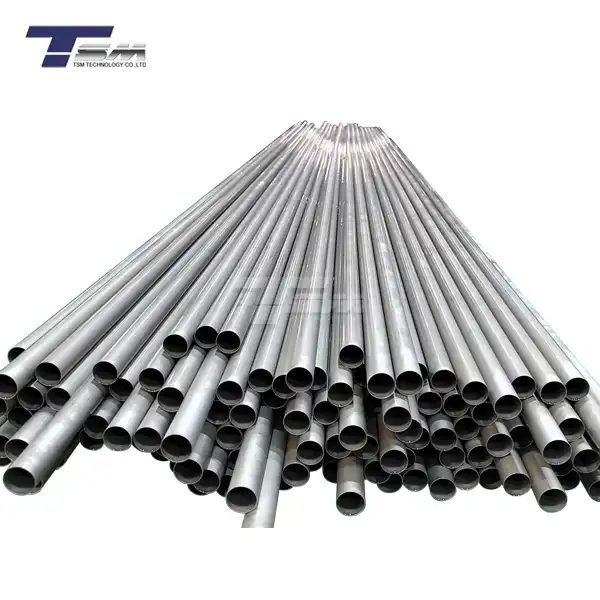

Production and Processing Technology

TSM Technology utilizes advanced manufacturing techniques, including:

- CNC machining

- Automated welding

- Heat treatment

- Precision forming

Production Process of Titanium Elbows

- Raw material selection and testing

- Cutting and shaping

- Heat treatment for stress relief

- CNC machining for precise dimensions

- Surface finishing (e.g., polishing, sandblasting)

- Quality inspection and testing

- Packaging and shipping

Quality Inspection

Our rigorous quality control process includes:

- Material composition analysis

- Dimensional checks

- Non-destructive testing (NDT)

- Hydrostatic pressure testing

- Surface finish inspection

Package and Shipping

Why Choose TSM Technology?

At TSM Technology, we pride ourselves on delivering cutting-edge material technology and unparalleled purity control. Our precision manufacturing capabilities ensure ultra-tight tolerances and custom surface treatments tailored to your specific needs. We maintain a comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications.

Our commitment to traceability, sustainable production, and resource efficiency sets us apart. We offer industry-specific customized solutions and rapid response to special requirements across the medical, energy, chemical, and aerospace sectors. With our global supply chain and strategic raw material reserves, we guarantee reliable delivery and consistent quality for all your titanium elbow needs.

Factory

FAQ

Q: What is the lead time for Titanium Elbows?

A: Standard lead times range from 2-4 weeks, depending on specifications and quantity.

Q: Can you provide custom sizes or angles?

A: Yes, we offer customization to meet your specific project requirements.

Q: Are your products suitable for cryogenic applications?

A: Our Grade 2 products are suitable for many cryogenic applications. Contact us for specific requirements.

Q: Do you provide material certifications?

A: Yes, we provide full material traceability and certification upon request.

Q: What is the minimum order quantity (MOQ)?

A: MOQ varies based on size and specification. Please contact us for details.

Contact Us

For inquiries or to discuss your product requirements about Titanium Elbows, please reach out to our team:

Email: info@tsm-technology.com

_1752550122066.webp)