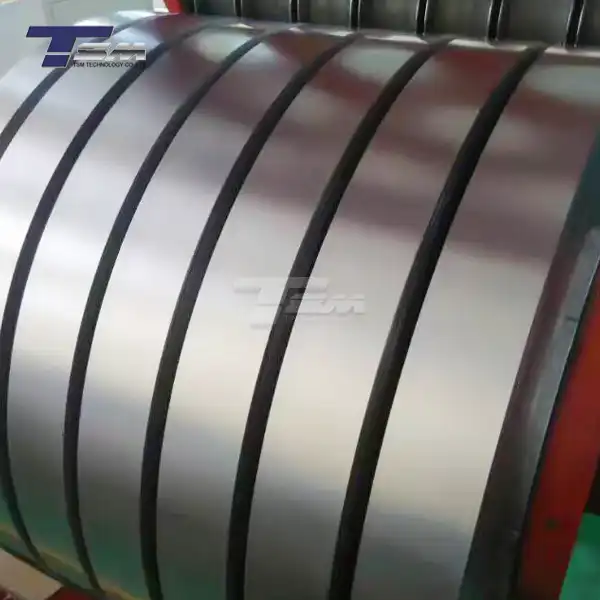

Titanium Foil

Supply Ability: 300 Tons/month

Grade: CP Titanium Gr.1 & Gr.2

Standard: ASTM B265, ASTM F67

Thickness: 0.03mm - 0.5mm (±0.005mm tolerance)

Width: 50mm - 600mm (slit edges available)

Vacuum annealed with oxide-free surface for medical/electronic applications.

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Foil Manufacturer and Supplier

TSM Technology Co., Ltd. is your premier manufacturer and supplier of high-quality Titanium Foil. With over a decade of expertise in superior nickel alloys and special metals, we've established ourselves as a trusted partner for precision engineering industries worldwide. Our products combine exceptional strength, corrosion resistance, and versatility, making them ideal for aerospace, medical, chemical processing, and electronic applications. At TSM, we're committed to delivering innovative solutions that meet the most demanding industry standards.

What is Titanium Foil?

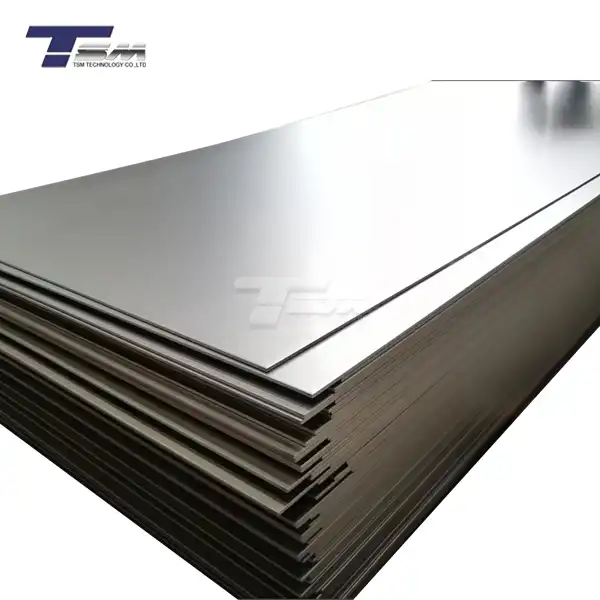

The Titanium Foil is a thin, flexible sheet of pure titanium or titanium alloy. It offers an excellent balance of strength-to-weight ratio, corrosion resistance, and biocompatibility. Our foils are available in various grades and thicknesses to suit diverse industrial needs.

Specifications

| Property | Value |

|---|---|

| Thickness Range | 0.005 mm - 1.0 mm |

| Width | Up to 1000 mm |

| Length | Custom cut to order |

| Grades | Grade 1, 2, 3, 4, 5 (Ti-6Al-4V) |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668°C (3034°F) |

| Tensile Strength | 240-890 MPa (depending on grade) |

| Yield Strength | 170-830 MPa (depending on grade) |

| Elongation | 15-24% (depending on grade) |

Product Standards

Our product meets or exceeds industry standards, including:

- ASTM B265

- AMS 4900-4911

- ASME SB-265

Features of Titanium Foil

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Excellent biocompatibility

- High temperature resistance

- Low thermal expansion

Applications

- Aerospace components

- Medical implants and devices

- Chemical processing equipment

- Heat exchangers

- Electrodes in advanced batteries

- Semiconductor manufacturing

Production and Processing Technology

At TSM Technology, we employ state-of-the-art production techniques to ensure the highest quality of Titanium Foil:

- Precision rolling to achieve ultra-thin gauges

- Advanced annealing processes for optimal grain structure

- Surface finishing options include bright annealed, matte, or customized textures

Production Process and Quality Inspection of Titanium Foil

TSM Technology's titanium foil production begins with certified raw materials, undergoing precision hot/cold rolling and annealing. Our rigorous QC includes XRF composition analysis, tensile/ultrasonic testing, surface roughness (Ra≤0.8μm) and dimensional checks (±0.01mm), ensuring ASTM/AMS compliance for aerospace and medical applications.

Why Choose TSM Technology?

At TSM Technology, we pride ourselves on delivering exceptional product solutions. Our advanced material technology ensures high-purity products with precise tolerances. We offer customized surface treatments like sandblasting, pickling, and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees compliance across all processes. We excel in traceability management and sustainable production practices, minimizing waste through efficient recycling. Our industry-specific expertise allows us to provide tailored solutions for the medical, energy, and aerospace sectors. With global supply chain capabilities and strategic raw material reserves, we ensure reliable, on-time delivery. Choose TSM for unparalleled quality, innovation, and customer-focused service in product manufacturing.

Package and Shipping

- Custom packaging to prevent damage during transit

- Global logistics support with expedited shipping options

- Full documentation and material certifications provided

FAQ

Q: What is the minimum order quantity for the product?

A: Our minimum order quantity varies based on the specific grade and dimensions. Please contact our sales team for details.

Q: Can you provide custom sizes or thicknesses?

A: Yes, we offer customization services to meet your specific requirements.

Q: What is the lead time for the product orders?

A: Standard lead times range from 2-4 weeks, depending on the product specifications and quantity.

Q: Do you offer samples before bulk orders?

A: Absolutely. We provide sample services to ensure our product meets your needs before large purchases.

Q: Is your product suitable for medical implants?

A: Yes, our medical-grade product meets stringent biocompatibility standards for implantable devices.

Contact Us

Ready to elevate your projects with premium Titanium Foil? Contact TSM Technology today for expert advice, custom quotations, or technical support.

Email: info@tsm-technology.com