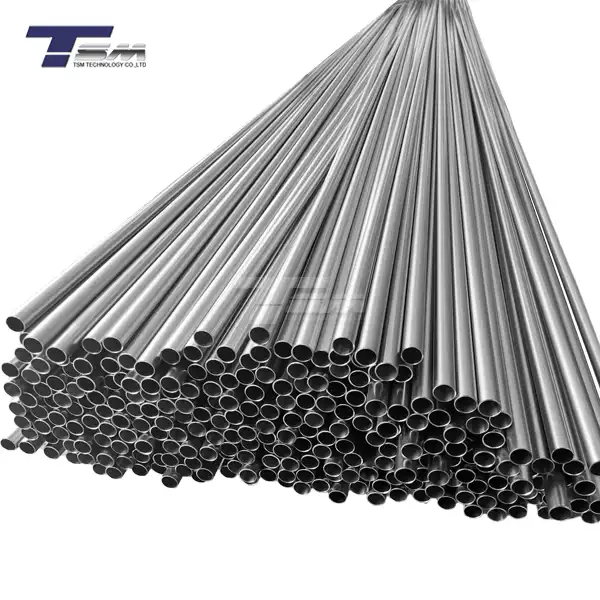

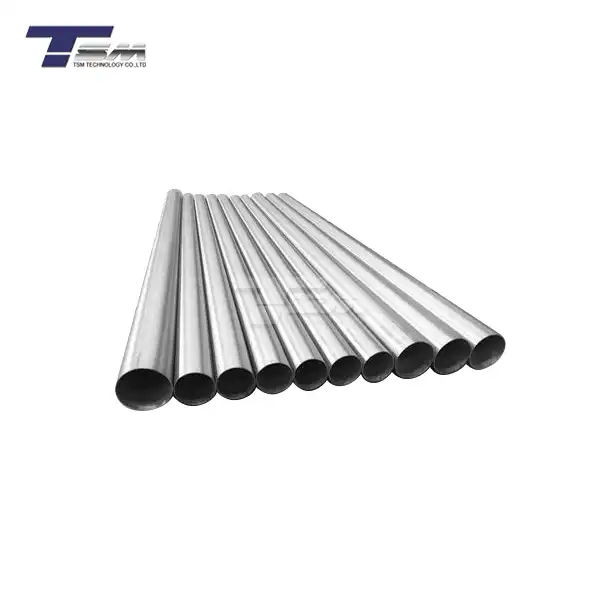

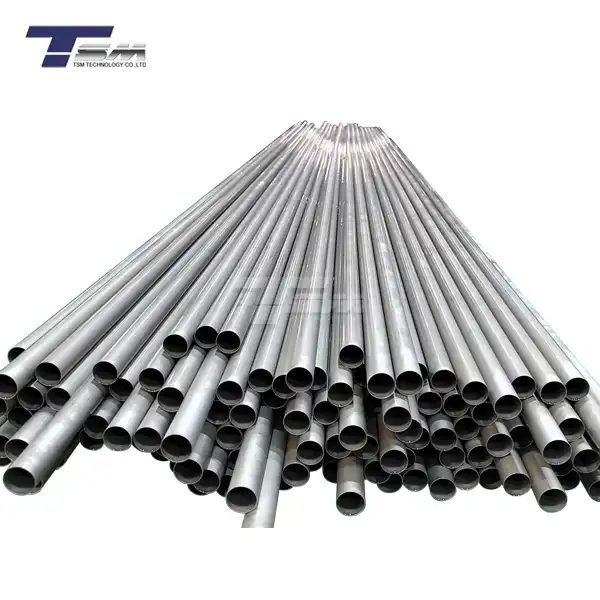

Titanium Welded Pipe

Supply Ability: 300 Tons/month

Grade:GR1/GR2/GR4/GR7/GR9/GR11/GR16/GR17

Standard: ASTM B862/AWS D1.9

Outside Diameter: 10-500 mm

Wall Thickness: 0.5-12 mm

Length: Standard 6,000mm (custom lengths available)

Features: 100% X-ray inspected welds, electropolished inner surface (Ra≤0.4μm)

Material Certification: MTC and SGS test reports available

Titanium Welded Pipes Manufacturer and Supplier

At TSM Technology Co., Ltd., we take pride in being a leading manufacturer and supplier of high-performance Titanium Welded Pipes. Our expertise in superior alloy production, coupled with advanced manufacturing techniques, ensures that our products meet the most stringent industry standards. We offer a wide range of titanium pipe solutions, catering to diverse applications across chemical, petrochemical, oil & gas, aerospace, and marine sectors.

What are Titanium Welded Pipes?

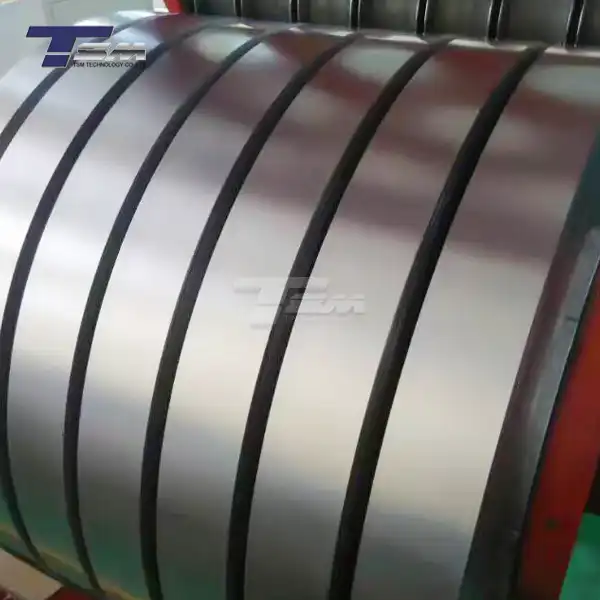

The Titanium Welded Pipes are high-strength, corrosion-resistant tubular products fabricated by welding titanium sheets or strips. These pipes combine the exceptional properties of titanium with precise welding techniques, resulting in reliable, long-lasting piping solutions for critical applications.

Specification

| Parameter | Value Range |

|---|---|

| Outer Diameter | 6mm - 1219mm |

| Wall Thickness | 0.5mm - 50mm |

| Length | Up to 12m (standard), custom lengths available |

| Grade | Grade 1, 2, 3, 4, 5, 7, 9, 11, 12 |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1668°C |

| Thermal Conductivity | 21.9 W/m·K |

| Tensile Strength | 240 - 1100 MPa (grade dependent) |

| Yield Strength | 170 - 970 MPa (grade dependent) |

Product Standards

Our products comply with international standards, including:

- ASTM B862

- ASME SB862

- ASTM B338

- JIS H4600

Production and Processing Technology

TSM Technology utilizes advanced welding technologies (TIG/Laser/Plasma) to produce high-integrity titanium pipes for critical applications. Our 7-stage process begins with certified Grade 1-12 titanium, progressing through precision forming, automated orbital welding, and stress-relieving heat treatment. Each pipe undergoes:

- 100% NDT: X-ray/ultrasonic weld inspection

- Surface Enhancement: Electropolishing (Ra≤0.4μm)

- Dimensional Verification: Laser scanning (±0.1mm tolerance)

Certified to ASTM B862/ASME SB862 standards, our pipes deliver:

✓ Zero porosity welds

✓ Superior corrosion resistance

✓ Consistent wall thickness

Quality Inspection and Equipment

TSM Technology enforces strict quality control with 100% visual inspection, radiographic and ultrasonic testing for defect detection, hydrostatic pressure validation, plus chemical and mechanical property verification to ensure product reliability.

Features of Titanium Welded Pipes

- Exceptional corrosion resistance

- High strength-to-weight ratio

- Excellent heat transfer properties

- Low thermal expansion

- Superior biocompatibility

- Resistance to erosion and cavitation

Applications

Titanium Welded Pipes find extensive use in:

- Oil & Gas – Offshore drilling platforms、high-temperature and high-pressure pipelines、oil and gas transportation

- Aerospace & Aviation – Engine parts、high-temperature corrosion-resistant systems)

- Marine Engineering– Seawater desalination equipment、ship corrosion-resistant pipelines

- Nuclear Industry – Nuclear fuel processing、nuclear reactor cooling systems

- Electronics – High-purity gas delivery, special electrode rod channel

Factory

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for products. Our cutting-edge material technology ensures high-purity products, while our precision manufacturing capabilities deliver ultra-tight tolerances. We offer customized surface treatments like sandblasting and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001, AS9100D, and NADCAP certifications, guarantees product integrity. With full traceability management and sustainable production practices, we provide tailored solutions for medical, energy, and aerospace sectors. Our global supply chain and strategic raw material reserves ensure consistent, timely deliveries, making us your reliable partner for all titanium piping needs.

Package and Shipping

TSM Technology provides tailored packaging solutions, including protective end caps, moisture-resistant wrapping, and reinforced wooden crating for international shipments. Our global logistics network ensures secure transport via air, sea, or land, with real-time tracking and expedited delivery options for urgent orders.

FAQ

Q1: What is the minimum order quantity for products?

A1: Our minimum order quantity varies based on pipe specifications. Please contact our sales team for detailed information.

Q2: Can you provide custom dimensions for products?

A2: Yes, we offer customization services to meet your specific requirements.

Q3: What is the lead time for the product orders?

A3: Lead times typically range from 2-6 weeks, depending on order volume and specifications.

Q4: Do you offer material certifications with your products?

A4: Yes, we provide full material traceability and certification documents upon request.

Q5: How do you ensure the quality of weld joints in your products?

A5: We employ advanced NDT techniques and 100% inspection protocols to guarantee weld integrity.

Contact Us

Ready to elevate your project with our premium Titanium Welded Pipes? Contact our expert team today for personalized assistance and quotations.

Email: info@tsm-technology.com

_1752550122066.webp)