Strategic Titanium Fastener Partnership: TSM & European Industrial Giants Reshape High-End Supply Chains

2022-08-25

I. Customer background and industry status

As a leading company in the field of industrial equipment manufacturing in Europe, Customer S enjoys a high reputation in the global industrial equipment market. Its products are widely used in many high-end industrial fields and have set a benchmark in the industry with excellent quality and leading technology. Since 2021, we have established a cooperative relationship with customer S and have become its strategic partner for 4 years, continuously supplying large-sized industrial fasteners to it.

II. Project challenges and requirements

(I) Procurement pain points

Customer S faces many key pain points when purchasing large-size titanium industrial fasteners such as M30, M42, and M68.

On the one hand, the quality stability of the products is extremely high, and it is necessary to ensure that the fasteners can operate reliably for a long time in a complex industrial environment; on the other hand, customers have strict requirements on delivery cycles and supply chain response speed to meet their efficient production plans. In addition, customers are also concerned about the problem of insufficient life of traditional stainless steel parts under specific working conditions, and how to control procurement costs while ensuring product performance.

(II) Technical Difficulties

From a technical perspective, this cooperation involves special materials such as pure titanium Grade 2, titanium alloy Grade 5, Grade 7, and Grade 12. These materials have characteristics such as high strength and high corrosion resistance, but they also bring huge challenges to machining.

The high hardness of the material leads to high cutting resistance, and the tool wear is serious during the machining process, which affects the machining efficiency and precision.

At the same time, customers have strict requirements on dimensional tolerances. How to accurately control dimensional accuracy in large-scale machining is a difficult problem before us.

III. Solutions and Product Details

(I) Customized Products

In response to customer needs, we customized a series of titanium fasteners for them.

In terms of materials, we strictly select high-quality grades such as pure titanium Grade 2, titanium alloy Grade 5, Grade 7, and Grade 12 to ensure that the products have excellent mechanical properties and corrosion resistance.

In terms of technology, we use advanced machining technology, from raw material cutting to fine processing, and each process is strictly controlled to meet customers' special requirements for large-size fasteners.

(II) Technical parameters

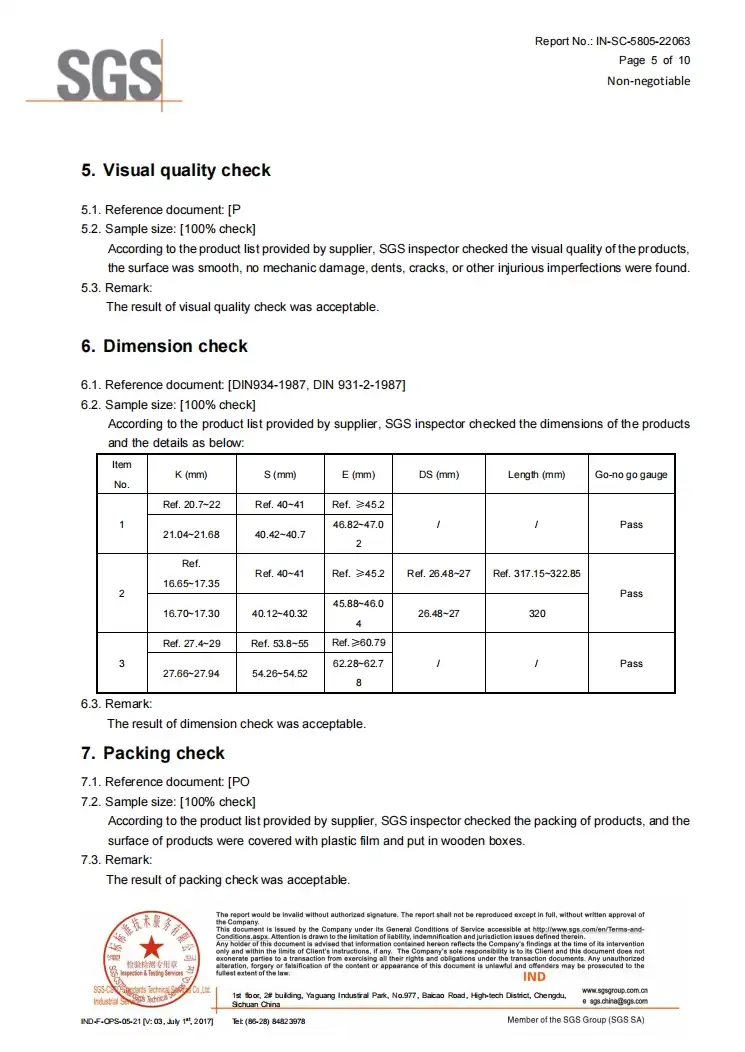

In terms of technical parameters, we ensure that the dimensional tolerance of the product is strictly controlled within the required range to meet customers' demand for high precision.

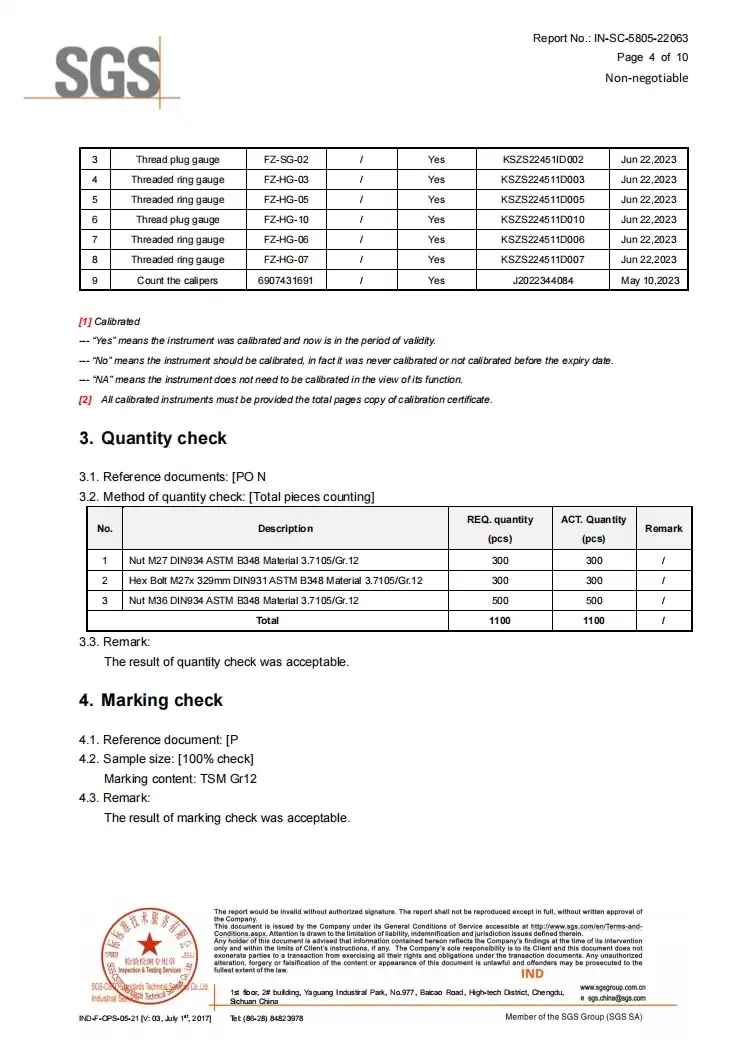

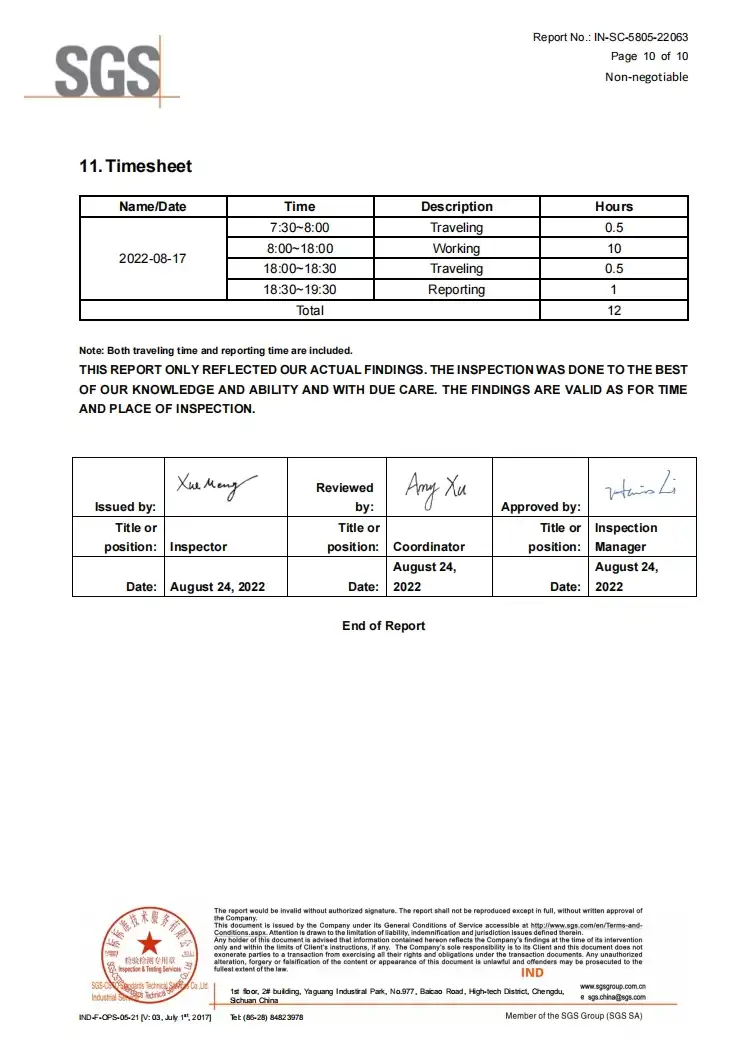

At the same time, the product has passed international authoritative third-party certification such as SGS. The relevant certification documents cover multiple key indicators such as material properties, mechanical properties, etc., which provide a strong guarantee for the quality of the product.

(III) Service highlights

In order to improve the efficiency of cooperation, we provide S customers with fast proofing services, providing customers with samples in a short time for customers to test and verify.

Throughout the project, we arranged a professional team to conduct full-process tracking and testing. From raw material procurement to product delivery, every link is strictly tested to ensure that the product quality meets customer requirements. At the same time, we maintain close communication with customers, understand customer needs and feedback promptly, and provide customers with a full range of services.

IV. Results and customer benefits

(I) Quantitative indicators

Through this cooperation, significant results have been achieved. Compared with the original stainless steel parts, the life of the titanium fasteners we provide has increased by 300%, greatly reducing the maintenance cost and downtime of customer equipment and improving the operating efficiency of the equipment. In terms of cost control, by optimizing processes and supply chain management, we have helped customers reduce procurement costs by 15%-25%, creating considerable economic benefits for them.

(II) Customer Testimonials

"It is a great pleasure to cooperate with TSM. The titanium fasteners they provide have exceeded our expectations in terms of quality and performance. The life of the products has been greatly improved, which provides a strong guarantee for the stable operation of our equipment. At the same time, the cost reduction also gives us more advantages in the market competition. We look forward to further deepening our cooperation in the future and achieving mutual benefit and win-win results."

- S Customer Purchasing Manager

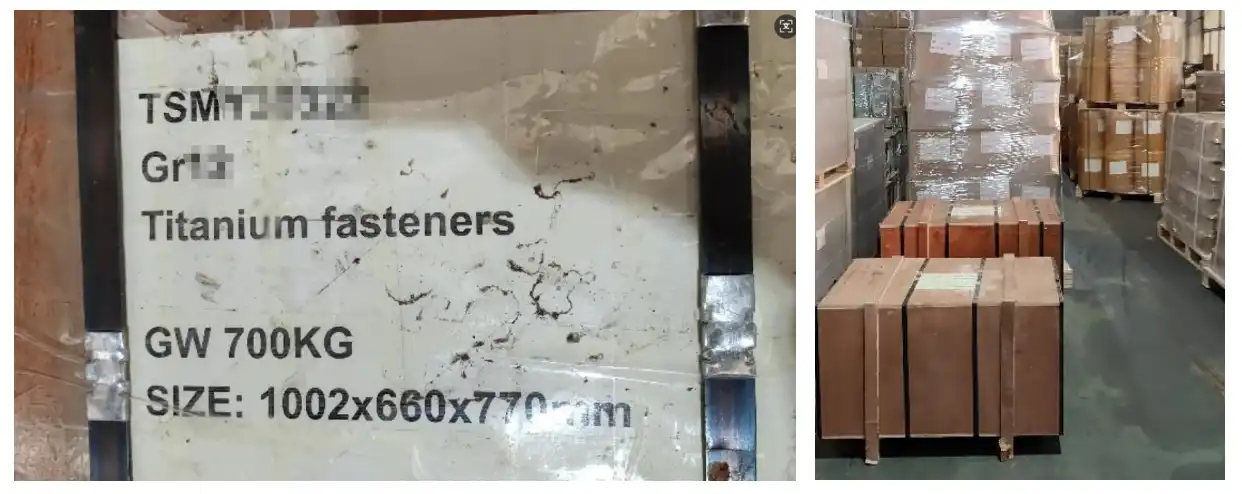

We have product detail photos, which clearly show the surface treatment, dimensional accuracy and other details of the fasteners; the packaging photos reflect our emphasis on product packaging and transportation, ensuring that the products are safely delivered to customers.

We provided a test report issued by a third-party testing agency such as SGS, with a key data page. The report lists in detail the various performance indicators of the product, such as tensile strength, yield strength, etc., which are in line with international standards and customer requirements.

(III) Project amount

The amount of the project is in the range of more than 100,000 US dollars. The specific figure cannot be disclosed due to confidentiality requirements, but it can be seen that this is a large-scale and significant cooperation project.

Our cooperation with customer S is a successful case. Through professional technology, high-quality products and considerate services, we have met the needs of customers, created value for customers, and also enhanced our competitiveness in the field of titanium fasteners. We believe that in future cooperation, we will continue to uphold the attitude of excellence and provide customers with better products and services.

_1752550122066.webp)