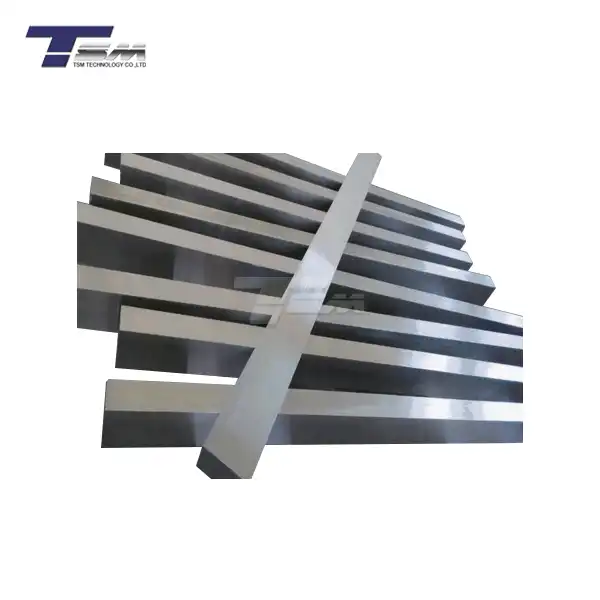

Can Titanium Plates Be Welded? Welding Techniques and Best Practices

2025-06-19

Titanium is a highly valuable metal in industries like aerospace, chemical processing, and marine engineering due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, welding titanium plates presents unique challenges due to their high reactivity with oxygen and nitrogen at elevated temperatures.

This article explores whether titanium plates can be welded, the best welding techniques, and key best practices to ensure strong, defect-free joints.

Can Titanium Plates Be Welded?

Yes, titanium plates can be welded, but they require strict process control to avoid contamination, cracking, and brittleness. The success of welding depends on:

- Material Grade (Commercially Pure Titanium vs. Titanium Alloys)

- Welding Method (TIG, MIG, Laser, EB, Friction Stir)

- Shielding Gas Purity (Argon or Helium)

- Pre- and Post-Weld Treatments

Best Welding Methods for Titanium Plates

| Welding Method | Advantages | Limitations |

|---|---|---|

| TIG (GTAW) | High precision, clean welds | Slow process, requires expert handling |

| MIG (GMAW) | Faster than TIG | Higher risk of contamination |

| Laser Welding | High speed, deep penetration | Expensive equipment |

| Electron Beam (EBW) | Vacuum prevents contamination | Limited to specialized applications |

| Friction Stir (FSW) | No filler material, solid-state process | Limited to certain plate thicknesses |

TIG (GTAW) is the most common method for welding titanium plates due to its precision and ability to maintain shielding gas coverage.

Key Challenges in Titanium Welding

1.Oxygen & Nitrogen Contamination

Titanium reacts with air above 400°C (752°F), forming brittle oxides.

Solution: Use high-purity argon (99.999%) and trailing gas shields.

2.Porosity & Cracking

Moisture, grease, or surface impurities can cause voids.

Solution: Thoroughly clean plates (acetone + stainless steel brush).

3.Heat-Affected Zone (HAZ) Embrittlement

Rapid cooling can lead to alpha-case (brittle layer).

Solution: Post-weld annealing (if required).

Best Practices for Welding Titanium Plates

Pre-Weld Preparation

-

Clean surfaces with acetone or alcohol to remove oils.

-

Use stainless steel brushes (avoid carbon steel to prevent contamination).

Shielding Gas Protection

-

Maintain argon coverage on both sides of the weld (back purging).

-

Use gas lenses for better shielding in TIG welding.

Controlled Heat Input

-

Avoid excessive heat to prevent warping and grain growth.

-

Use pulse TIG for thin plates.

Post-Weld Inspection

-

Check for discoloration (straw/yellow = acceptable; blue/gray = contaminated).

-

Conduct X-ray or ultrasonic testing for critical applications.

Conclusion

Titanium plates can be successfully welded with the right techniques, equipment, and precautions. TIG welding with argon shielding remains the gold standard, while advanced methods like laser and electron beam welding are ideal for high-precision applications.

By following strict cleaning, shielding, and heat control protocols, manufacturers can achieve strong, corrosion-resistant titanium welds for demanding industries.

_1752550122066.webp)