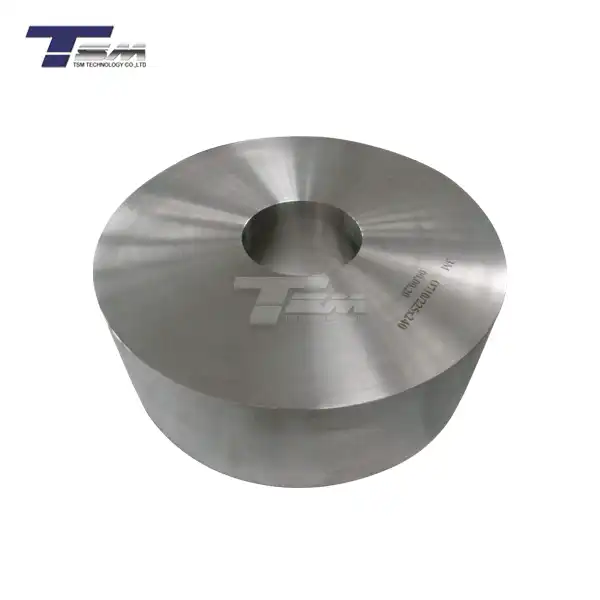

Titanium Forged Ring

Supply Ability: 300 Tons/month

Grade: F1、F2、F4、F5、F7、F9、F12

Standard: ASTM B381

OD: 200mm - 3500mm

ID: 100mm - 3000mm

Height: 50mm - 800mm

Radial-axial forged for aerospace bearing applications.

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Titanium Forged Rings Manufacturer and Supplier

At TSM Technology Co., Ltd., we're your trusted manufacturer and supplier of high-quality Titanium Forged Rings. With over 14 years of experience in superior alloy solutions, we've mastered the art of creating these essential components for the aerospace, medical, and chemical processing industries. Our products offer unparalleled strength, corrosion resistance, and dimensional accuracy, making them the go-to choice for precision engineering applications worldwide.

What are Titanium Forged Rings?

The Titanium Forged Rings are high-performance components created through a precision forging process. This method enhances the titanium's already impressive properties, resulting in rings with exceptional strength-to-weight ratios and superior resistance to extreme environments.

Specifications

| Property | Value |

|---|---|

| Diameter Range | 100mm - 2000mm |

| Wall Thickness | 10mm - 500mm |

| Weight | Up to 5000 kg |

| Grades Available | Grade 2, Grade 5 (Ti-6Al-4V), Custom Alloys |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.43 g/cm³ (Grade 5) |

| Melting Point | 1604-1660°C |

| Yield Strength | 830-924 MPa (Grade 5) |

| Elongation | 10% (minimum) |

| Corrosion Resistance | Excellent |

Product Standards

Our products meet or exceed industry standards, including:

- ASTM B381

- AMS 4928

- ASME SB-381

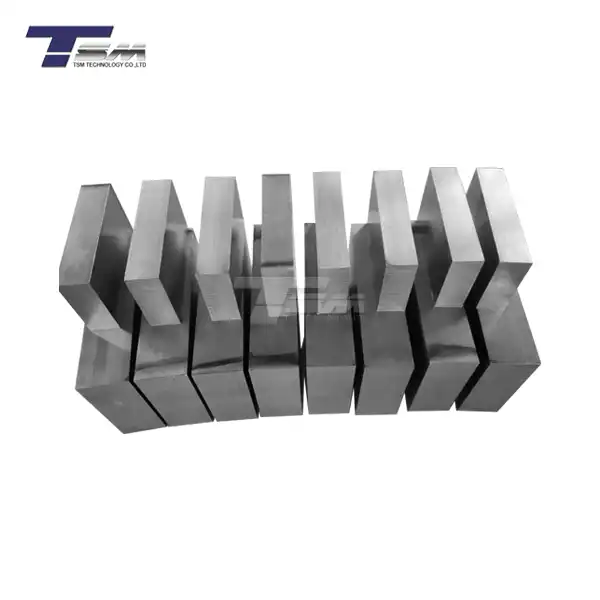

Features of Titanium Forged Rings

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- High-temperature performance

- Excellent biocompatibility

- Low thermal expansion

Production Process of Titanium Forged Rings

Our titanium forged rings are produced through a rigorous manufacturing process that begins with meticulous raw material selection of premium-grade titanium alloys. The selected billets undergo controlled preheating to achieve optimal forging temperatures before being precision-formed using advanced hydraulic presses. This forging process enhances the material's grain structure and mechanical properties.

Following forging, each ring undergoes specialized heat treatment to optimize its strength, durability, and corrosion resistance characteristics. Our state-of-the-art CNC machining centers then precisely machine the rings to meet exact dimensional specifications. Optional surface treatments are available to meet specific application requirements.

Quality Inspection

Every product undergoes rigorous testing:

- Dimensional accuracy checks

- Non-destructive testing (NDT)

- Chemical composition analysis

- Mechanical property verification

- Surface quality assessment

This complete process ensures our titanium forged rings meet the most demanding specifications for aerospace, energy, and industrial applications, delivering unmatched performance and reliability.

Applications

TSM Technology's precision titanium forged rings serve critical functions across industries, including aerospace (jet engine components, structural parts), medical (surgical implants, diagnostic equipment), and energy (oil/gas drilling tools, chemical processing systems). Our rings also excel in marine applications (propulsion systems, subsea components) where corrosion resistance and strength are paramount. Manufactured to meet stringent industry standards, these high-performance rings deliver reliability in the most demanding operating environments.

Factory

Why Choose TSM Technology?

At TSM Technology, we're not just manufacturers; we're your partners in innovation and quality. Our advanced material technology ensures high-purity titanium alloys, while our precision manufacturing capabilities deliver ultra-tight tolerances and customized surface treatments. We're ISO 9001/13485/AS9100D certified, offering full traceability and sustainable production practices.

Our industry-specific solutions cater to the medical, energy, and aerospace sectors, backed by a global supply chain and strategic raw material reserves. With TSM, you're choosing a responsive, reliable partner committed to your success.

Package and Shipping

TSM Technology ensures secure delivery of titanium forged rings with custom wooden crates/pallets and vacuum-sealed anti-corrosion packaging. Our global logistics network provides reliable shipping, customs clearance support, and on-time delivery worldwide.

FAQ

Q: What's the lead time for custom products?

A: Typically 4-6 weeks, depending on specifications and quantity.

Q: Can you provide material certifications?

A: Yes, we provide full material traceability and test reports with every order.

Q: Do you offer post-forging machining services?

A: Absolutely. We provide comprehensive in-house machining to meet your exact specifications.

Q: What's the minimum order quantity (MOQ)?

A: Our MOQ varies based on ring size and complexity. Contact us for specific details.

Q: How do you ensure consistent quality across large orders?

A: We employ stringent quality control measures and advanced process monitoring throughout production.

Contact Us

Ready to elevate your engineering projects with our superior Titanium Forged Rings? Contact our expert team today for personalized solutions and competitive quotes.

Email: info@tsm-technology.com