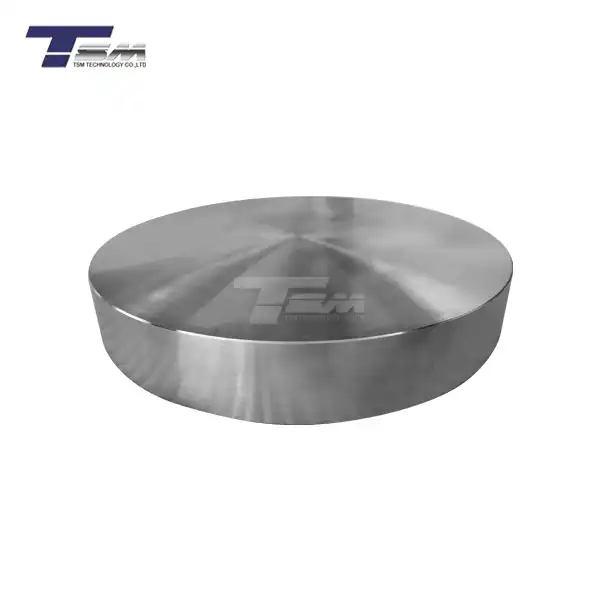

Nickel Alloy SO Flange

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: MONEL 400, INCONEL 600/625

Standard: ASME B16.5

Size Range: ½" - 24"

Special: Available with raised face or flat face

Surface treatments: sandblasting/anodizing

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy SO Flanges Manufacturer and Supplier

Welcome to TSM Technology Co., Ltd., your trusted manufacturer and supplier of high-quality Nickel Alloy SO Flanges. With over 14 years of expertise in superior alloy solutions, we deliver unparalleled quality and reliability to industries worldwide. Our products are engineered to excel in the most demanding environments, offering exceptional corrosion resistance and durability for critical applications.

What are Nickel Alloy SO Flanges?

The Nickel Alloy SO Flanges are specialized pipe fittings designed for use in high-pressure, high-temperature, and corrosive environments. These flanges are crafted from premium nickel alloys, such as Inconel, Monel, or Hastelloy, to provide superior performance in challenging industrial settings.

Specifications

| Property | Detail |

|---|---|

| Material | Nickel Alloys (Inconel, Monel, Hastelloy) |

| Type | Slip-On (SO) |

| Size Range | 1/2" to 24" |

| Pressure Class | 150# to 2500# |

| Face Type | Raised Face, Flat Face |

| Standards | ASME B16.5, ASTM B564 |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 690-1380 MPa |

| Yield Strength | 280-760 MPa |

| Elongation | 30-50% |

| Hardness | 160-350 HB |

| Corrosion Resistance | Excellent |

| Temperature Range | -196°C to 1000°C |

Product Standards

Our products are manufactured in compliance with international standards, including:

- ASME B16.5

- ASTM B564

- NACE MR0175 / ISO 15156

- PED 2014/68/EU

Features of Nickel Alloy SO Flanges

- Exceptional corrosion resistance in aggressive environments

- High strength-to-weight ratio

- Excellent thermal stability

- Superior weldability and formability

- Resistant to stress-corrosion cracking

- Long service life in extreme conditions

Applications

Nickel Alloy SO Flanges are crucial components in various industries:

- Oil & Gas: Offshore platforms, subsea equipment

- Chemical Processing: Reactors, heat exchangers

- Power Generation: Steam turbines, nuclear reactors

- Aerospace: Engine components, exhaust systems

- Marine: Seawater cooling systems, desalination plants

Production and Processing Technology

At TSM Technology, we employ cutting-edge manufacturing techniques to ensure the highest quality:

- Precision CNC machining

- Advanced heat treatment processes

- Specialized surface finishing options

- Stringent quality control at every stage

Production Process of Nickel Alloy SO Flanges

- Raw material selection and testing

- Forging or casting of flange blanks

- Precision machining to specified dimensions

- Heat treatment for optimal mechanical properties

- Surface finishing (e.g., polishing, passivation)

- Final inspection and quality assurance

Quality Inspection

Our rigorous quality control process includes:

- Material composition analysis

- Dimensional checks

- Non-destructive testing (NDT)

- Hydrostatic pressure testing

- PMI (Positive Material Identification)

Package and Shipment

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for products due to our comprehensive expertise and commitment to excellence. We offer cutting-edge material technology with superior purity control, ensuring the highest grade alloys for your applications. Our precision manufacturing capabilities deliver ultra-tight tolerances and customized surface treatments, meeting the most stringent requirements for biomedical inertness or chemical corrosion resistance.

With certifications including ISO 9001/13485, AS9100D, and NADCAP, we guarantee full regulatory compliance. Our end-to-end traceability system, sustainable production practices, and industry-specific solutions demonstrate our dedication to quality and innovation. Backed by a global supply chain and strategic raw material reserves, we provide rapid response times and reliable delivery for all your specialized flange needs.

TSM customers and Exhibition

FAQ

- Q: What alloys are available for SO flanges?

A: We offer a range of nickel alloys, including Inconel, Monel, and Hastelloy. - Q: Can you provide custom dimensions for SO flanges?

A: Yes, we specialize in custom fabrication to meet your specific requirements. - Q: What is the typical lead time for products?

A: Standard sizes are usually available in 2-4 weeks, while custom orders may take 4-6 weeks. - Q: Do you provide material test reports (MTRs)?

A: Absolutely. We provide comprehensive MTRs with every order upon request. - Q: Are your flanges suitable for high-temperature applications?

A: Yes, our nickel alloy flanges are designed to withstand temperatures up to 1000°C.

Contact Us

Ready to elevate your project with premium Nickel Alloy SO Flanges? Contact our experts today for personalized solutions and competitive quotes.

Email: info@tsm-technology.com

_1752550122066.webp)