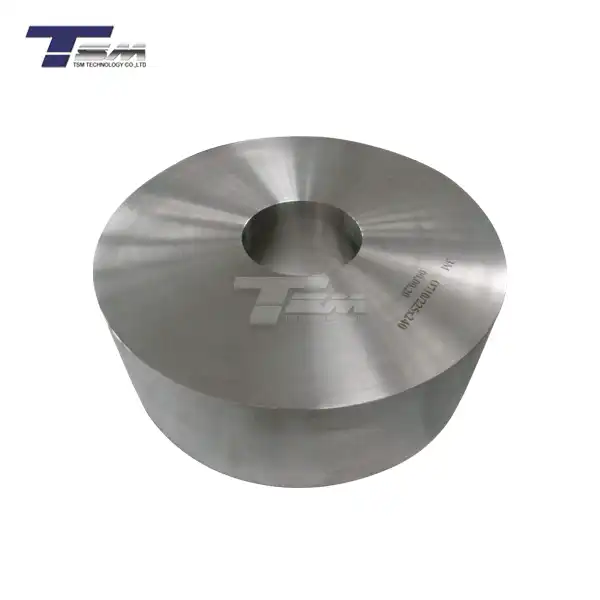

Titanium Forged Disc

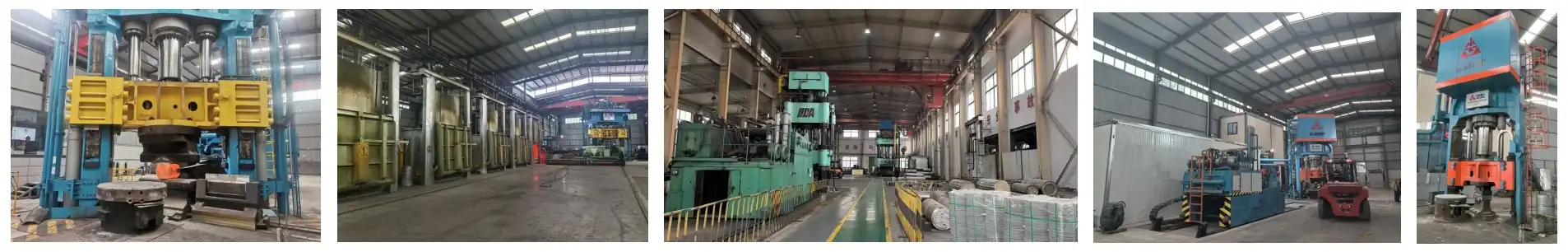

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: F1、F2、F4、F5、F7、F9、F12

Standard: ASTM B381, AMS 4928

Diameter: 100mm - 2000mm

Thickness: 20mm - 300mm

Ultrasonically tested with 100% microstructure inspection reports.

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

TSM: Your Premier Titanium Forged Disc Manufacturer

At TSM Technology, we specialize in producing superior Titanium Forged Discs for industries that demand excellence. With over 14 years of experience, we've established ourselves as a leading manufacturer and supplier of high-quality titanium components. Our advanced manufacturing processes and stringent quality control ensure that our products meet the most exacting standards for aerospace, medical, and industrial applications.

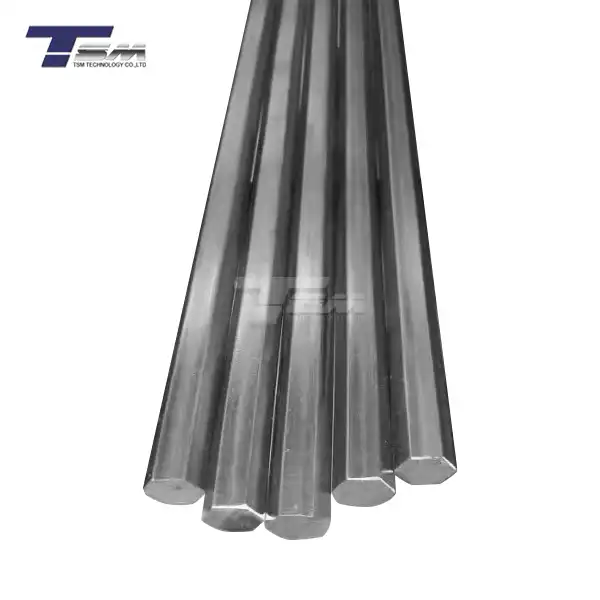

What are Titanium Forged Discs?

The Titanium Forged Discs are precision-engineered components crafted from high-grade titanium alloys. These discs are created through a sophisticated forging process that enhances their mechanical properties, making them ideal for applications requiring exceptional strength, corrosion resistance, and lightweight performance.

Specifications

| Property | Value |

|---|---|

| Diameter Range | 50mm - 1000mm |

| Thickness Range | 10mm - 300mm |

| Weight | Up to 500kg |

| Alloy Grades | Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Custom |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 4.43 g/cm³ (Ti-6Al-4V) |

| Tensile Strength | 900-1200 MPa |

| Yield Strength | 830-1100 MPa |

| Elongation | 10-15% |

| Melting Point | Approx. 1650°C |

Product Standards

- ASTM B381

- AMS 4928

- ISO 5832-3 (for medical applications)

Features of Titanium Forged Discs

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- High-temperature performance

- Excellent fatigue resistance

- Biocompatibility for medical applications

Applications

- Aerospace: Engine components, structural parts

- Medical: Implants, surgical instruments

- Industrial: Chemical processing equipment, marine applications

- Energy: Turbine components, offshore equipment

Production Process of Titanium Forged Discs

TSM Technology produces premium titanium forged discs through a controlled manufacturing process. We begin with certified material selection and testing, followed by precise billet preheating. Our hydraulic presses perform high-precision forging to achieve optimal grain structure, with subsequent heat treatment enhancing mechanical properties. Each disc undergoes CNC machining to exacting dimensional tolerances, with optional surface treatments available. Rigorous quality inspections, including NDT testing, dimensional verification and mechanical property analysis, ensure product reliability for critical aerospace, energy and industrial applications.

Quality Inspection

- Non-destructive testing (NDT): Ultrasonic, X-ray, and dye penetrant inspections

- Mechanical property testing

- Dimensional accuracy checks

- Microstructure analysis

Factory

Why Choose TSM Technology?

TSM Technology stands out as your ideal partner for Titanium Forged Discs. Our cutting-edge material technology ensures high-purity titanium alloys, while our precision manufacturing capabilities deliver ultra-tight tolerances. We offer customized surface treatments like sandblasting and polishing to meet specific industry needs. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees product excellence. We excel in traceability management and sustainable production practices. Our industry-specific solutions cater to medical, energy, and aerospace sectors, supported by a robust global supply chain and strategic raw material reserves. Choose TSM for unparalleled expertise and reliability in titanium forging.

Package and Shipping

FAQ

Q: What is the minimum order quantity for products?

A: We can accommodate orders starting from 1 piece for prototyping to large bulk orders.

Q: Can you provide custom sizes and alloys?

A: Yes, we offer customization services to meet your specific requirements.

Q: What is the typical lead time for products?

A: Lead times vary based on specifications and quantity, typically ranging from 2-8 weeks.

Q: Do you provide material certifications?

A: Absolutely. We provide full material certifications and test reports with every order.

Q: Are your products suitable for medical implants?

A: Yes, we produce medical-grade titanium discs that meet ISO 5832-3 standards for implants.

Contact Us

Ready to elevate your projects with our premium Titanium Forged Discs? Contact our expert team today for personalized solutions and quotes.

Email: info@tsm-technology.com