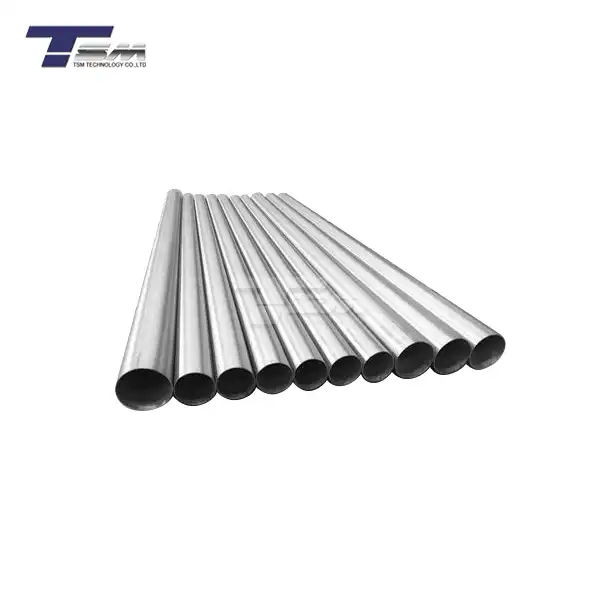

Nickel Alloy Straight Wire

3 factories*8 production lines*70+ machines

Supply Ability: 300 Tons/month

Grade: Nickel 200, MONEL 400, INCONEL 600

Standard: ASTM B166

Diameter: 0.5mm - 12.0mm

Length: 500mm - 3000mm (±1mm tolerance)

Surface: Bright annealed or centerless ground

Custom Services: Non-standard sizes, special tolerances (±0.05mm)

Material Certification: MTC and SGS test reports available

Delivery time: Usually about 10-25 days(According to your order quantity)

Nickel Alloy Straight Wire Manufacturer and Supplier

TSM Technology Co., Ltd. is a leading manufacturer and supplier of Nickel Alloy Straight Wire. With over 14 years of experience, we've built a reputation for delivering superior quality and innovative solutions. Our products offer exceptional corrosion resistance, high-temperature stability, and durability for demanding industrial applications. Trust TSM for precision-engineered alloy wire that meets the strictest industry standards.

What are Nickel Alloy Straight Wires?

The Nickel Alloy Straight Wires are high-performance materials designed for critical applications in aerospace, chemical processing, and energy sectors. These wires combine nickel with other elements to create alloys with superior properties.

Specifications

| Property | Value |

|---|---|

| Diameter Range | 0.1mm - 12mm |

| Length | Custom (up to 6m) |

| Surface Finish | Bright, Matte, or Custom |

| Straightness | ≤0.5mm/m |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 450-1600 MPa |

| Yield Strength | 200-1000 MPa |

| Elongation | 15-50% |

| Melting Point | 1300-1450°C |

| Density | 8.0-8.9 g/cm³ |

Product Standards

- ASTM B164, B166, B167

- AMS 5665, 5687

- ISO 6207, 9723

Features of Nickel Alloy Straight Wire

- Excellent corrosion resistance

- High-temperature strength

- Superior mechanical properties

- Exceptional fatigue resistance

- Versatile for various applications

Applications

Our Nickel Alloy Straight Wire finds use in:

- Aerospace components

- Chemical processing equipment

- Oil and gas industry

- Medical devices

- Nuclear power plants

Production and Processing Technology

TSM employs advanced manufacturing techniques to ensure the highest quality product:

- Precision melting and casting

- Hot working and cold drawing

- Heat treatment for optimal properties

- Rigorous quality control at each stage

Quality Inspection

We maintain strict quality standards:

- XRF analysis for composition verification

- Mechanical testing for strength and ductility

- Dimensional checks for precise tolerances

- Surface inspections for finish quality

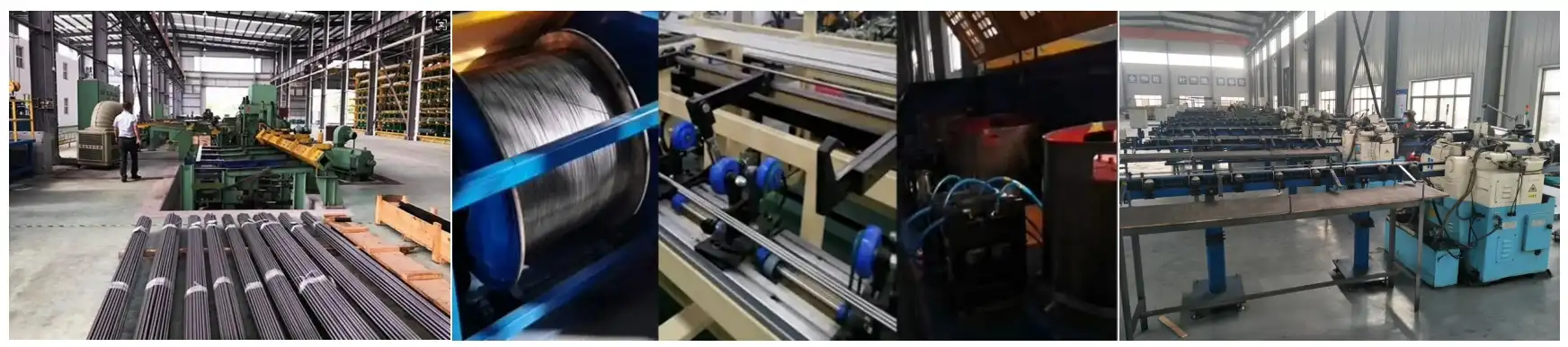

Factory and Equipment

Why Choose TSM Technology?

TSM Technology stands out as your premier choice for products. Our cutting-edge material technology ensures high-purity alloys with precise composition control. We excel in precision manufacturing, offering ultra-tight tolerances and customized surface treatments. Our comprehensive quality assurance system, backed by ISO 9001/13485, AS9100D, and NADCAP certifications, guarantees product reliability. We provide full traceability and employ sustainable production methods. With industry-specific solutions and rapid response capabilities, we cater to diverse sectors including medical, energy, and aerospace. Our global supply chain and strategic raw material reserves ensure consistent availability and timely delivery of your product needs.

Package and Shipping

FAQ

Q: What alloy grades do you offer for straight wire?

A: We offer a wide range, including Inconel, Monel, and Hastelloy grades.

Q: Can you provide custom diameters?

A: Yes, we can produce wire to your exact specifications.

Q: What is the minimum order quantity?

A: MOQs vary by alloy and diameter. Contact us for details.

Q: Do you provide material certifications?

A: Yes, we provide full material test reports (MTRs) with every order.

Q: What is the typical lead time for orders?

A: Standard lead times are 2-4 weeks, with expedited options available.

Contact Us

Ready to elevate your projects with premium Nickel Alloy Straight Wire? Contact TSM Technology today:

Email: info@tsm-technology.com